Diamond Light Source, the UK’s national synchrotron science facility located in Oxfordshire, has appointed Inspec Solutions, a leading independent control, safety & automation systems supplier to the UK’s energy, metals, chemicals, oil & gas and manufacturing industries, to provide Functional Safety Services across its operations.

Inspec Solutions was approached by the organisation to help meet its demanding proof test schedule as Diamond recognised the importance of effective high integrity automatic safety systems to protect hazardous processes.

Because of its expertise in delivering customer-critical infrastructure, Inspec Solutions will be able to deploy a team and begin testing, which would allow Diamond staff to focus on their core working duties.

Mark Ritson, Managing Director of Inspec Solutions, explains: “We are really excited to be working with Diamond Light Source on this important project. Diamond should save a significant amount of time by outsourcing this service. They will benefit from our ability to operate as a highly qualified independent company to verify the integrity of their safety system. By having certified Functional Safety Engineers in the team, we will provide a fresh, thorough, and ongoing review of the existing proof test procedures, highlighting opportunities for improvements.”

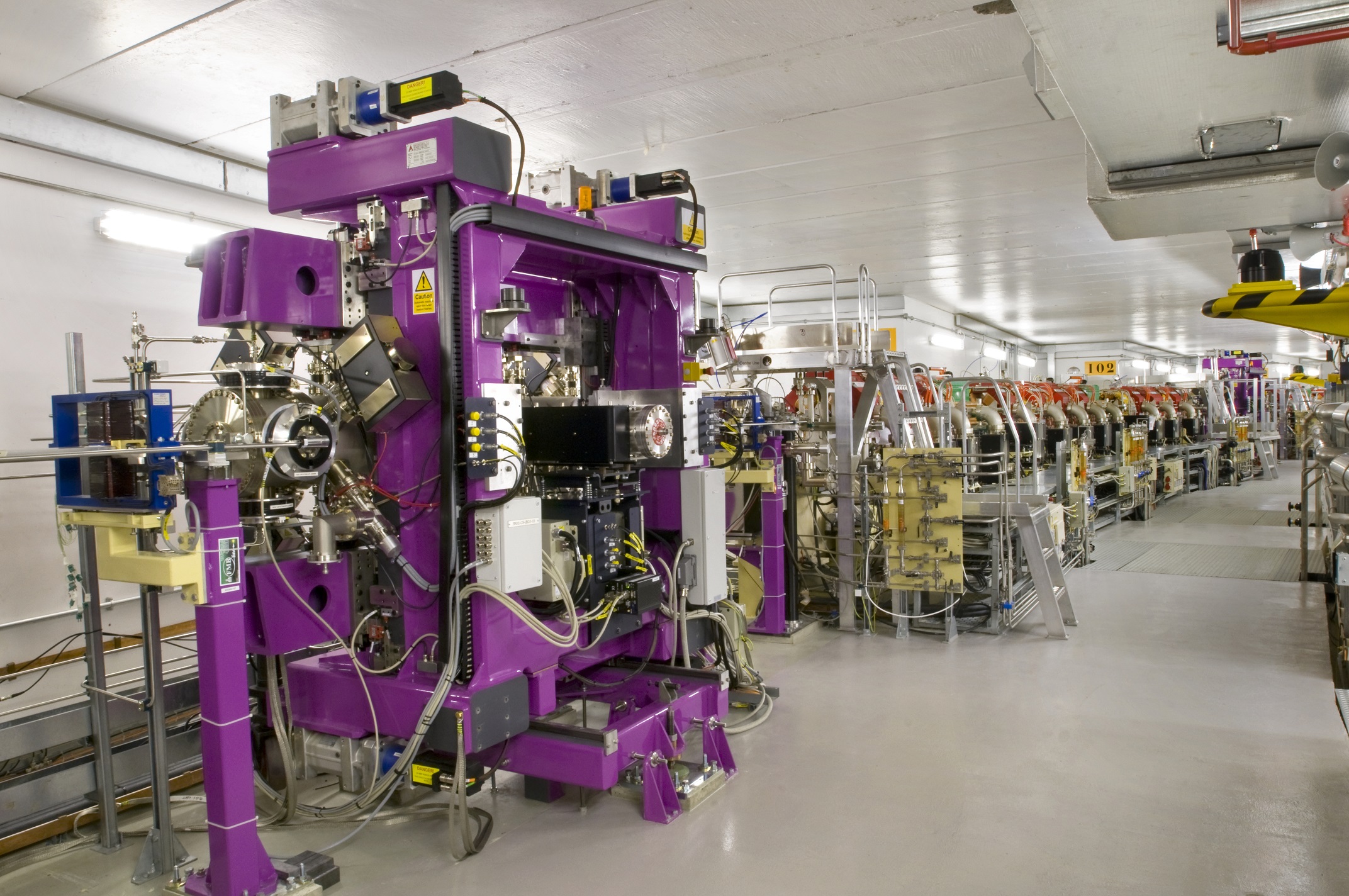

Diamond is one of the most advanced scientific facilities in the world and its pioneering capabilities are helping to keep the UK at the forefront of scientific research. Its technology accelerates electrons to near light speeds so that they give off light 10 billion times brighter than the sun. This allows scientists to use the light to study a vast range of subject matter, from new medicines and treatments for disease to innovative engineering and cutting-edge technology.

The Inspec Solutions team supporting Diamond includes certified TÜV Functional Safety Engineers, as well as highly experienced offshore technicians with backgrounds in supporting critical infrastructure in the UK North Sea.

Inspec Solutions has over 15 years of Functional Safety experience in many different industries, focusing on both continuous process and machinery installations.

This experience means the company can carry out proof testing on safety critical systems to a very high standard and to work with clients to improve their own procedures. Including a certified Functional Safety Engineer in the team provided a fresh and thorough review over the existing proof test procedures, highlighting opportunities for improvements.

The

company provides high integrity, SIL rated systems and offers every stage of

the safety lifecycle from Risk Assessment / HAZOP / LOPA, SRS, through design,

installation, validation or and SIF proof testing services.