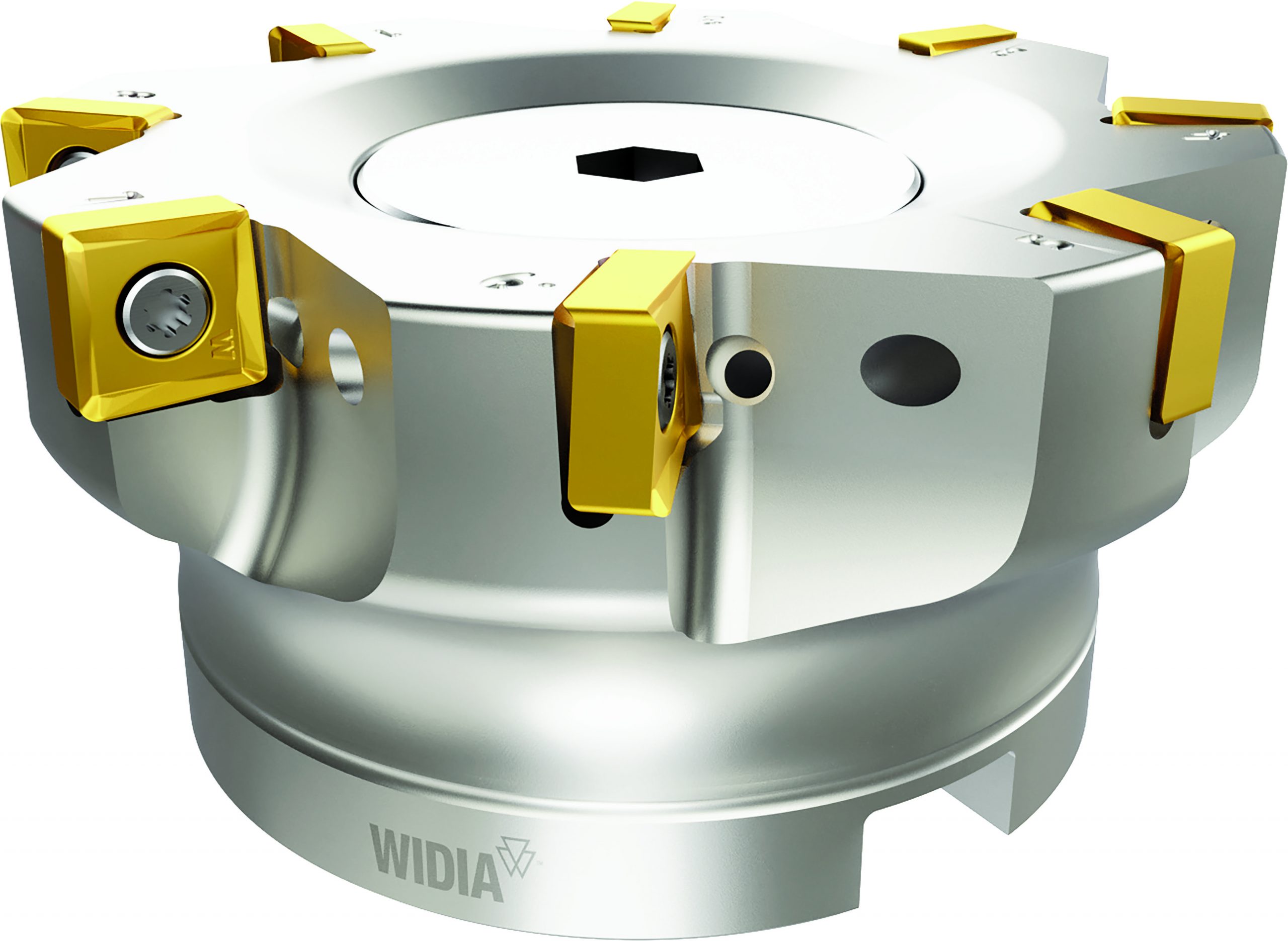

Extending the capabilities of its milling portfolio, Industrial Tooling Corporation (ITC) has now expanded the VSM890-12 face and shoulder milling series from Widia. Hailed as one of the very few 8-edged double-sided milling lines with genuine 90-degree milling, the VSM890-12 has been increased with the arrival of its new MM insert geometry.

The high-performance milling line generates superior metal removal rates on a complete range of materials when conducting face, shoulder, Z-axis and contour plunging and 100% radial engagement slotting. This operational diversity is a credit to the availability of a coarse, medium or fine pitch insert density that corresponds with a new pocket seat design that enhances stability and rigidity during roughing applications.

To achieve this performance in a wide range of materials, Widia has developed three insert geometries. The ALP geometry has been developed as the first-choice grade and geometry for the machining of nonferrous materials and this is complemented by the ML inserts for the semi-finish and finish machining of stainless steel. However, to extend the capabilities of the VSM 890-12 to a wider audience, Widia has now introduced the new MM insert designation. This new grade is a general-purpose insert that is perfect for material types from steel and stainless to iron, super-alloys and hard materials. The ability to cater to this expansive range of materials is a credit to the unique insert geometry, substrate and innovative new coating that have all been developed by Widia.

The new VSM890 series is available with a 32mm diameter Weldon end mill configuration whilst the shell mill tool bodies are available in diameters from 40mm up to 250mm with a cartridge face mill providing a 315mm diameter. The most impressive feature of the WSM890 is its true 90 degrees cutting for wall and step milling. With an integrated wiper facet and super positive rake design on the inserts, the VSM890 generates exceptional surface finishes and an efficient and smooth cutting action for low-powered machines. Now, ITC can offer this extremely cost-effective milling solution for a wider audience and a greater application range with the new MM inserts.