The manufacturing industry has become increasingly connected, allowing the sector to enjoy benefits ranging from becoming more agile and competitive in the market, to maximising efficiency, reducing costs, and monetising data. It is clear that implementing smart manufacturing is no longer a choice but a necessity for survival. However, as the industrial sector continues to evolve and expand, it is more essential than ever that companies modernise their networks to securely support increased connectivity.

Increased connectivity expands the potential attack surface, as vendors, contractors, and maintenance access data from remote locations. With an increase in connected applications and devices, there is a greater need for cybersecurity to ensure production continuity and safety. Using the latest networking technologies not only addresses cybersecurity risks, but allows companies to break down data silos, harnessing the power of greater connectivity and information sharing. This can help manufacturers to make real-time operational decisions and improve productivity in new ways.

Prioritising the modernisation of network systems will revolutionise the manufacturing industry, improving communication and productivity across organisations and their stakeholders.

The benefits of increased connectivity in the manufacturing industry

Connectivity is critical in manufacturing today, not just within organisations, but extending across a wider web of connected partners, suppliers, contractors, and customer communities. Visibility to these far-reaching corners is essential as manufacturers rely on a chain of partners to help overcome modern challenges and meet customer demands. For instance, shortages in materials means that manufacturers are increasingly turning to co-innovators, component suppliers, and a global supply chain to help design and deliver innovative products. This approach is more than just sharing data, secure networks are needed to coordinate large scale operations efficiently, remotely and securely.

Smart manufacturing allows organisations to improve output as efficient data access allows companies to track their KPIs and improve processes. This timely data helps maintenance technicians to get ahead of downtime issues and remote mobile device connections allow subject matter specialists to address system problems immediately. Efficient data also allows for self-aware and system-aware assets which can automatically make adjustments to optimise processes and keep production running, with less need for human intervention.

Beyond productivity, modern industrial network architecture can also benefit the manufacturing industry in other key areas. The ability to access and analyse safety-system data can allow managers to better understand risks, enhance safety and ease compliance within industrial processes. Remote network connections through mobile devices can deliver information to workers in a familiar and convenient format. The ability to track virtually every point in a product’s lifecycle from raw-ingredient receipt to supply-chain shipments can improve quality and ensure punctual deliveries.

Modernising network systems

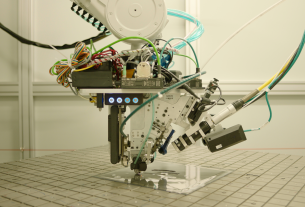

For most organisations, network modernisation involves an intersection of information-technology and operations-technology systems into a converged network architecture. This establishes a common, connected and standardised infrastructure in which people, processes and technologies can be seamlessly connected. Although each modernisation project is unique, there are general considerations that organisations should consider to optimise network design and proactively address risks.

The modernisation of network infrastructure requires organisation-wide collaboration to identify and address potential risks. Collaboration is key to determining the necessary connections between the manufacturing execution system and enterprise business systems to ensure relevant teams have access to the information they need. When modernising networks, it is essential that organisations consider coordinating safety and security efforts to help identify and mitigate potential risks that could arise from security or safety incidents.

The manufacturing industry is increasingly under threat from cyberattacks. These attacks can be detrimental to manufacturers as they are vulnerable to both typical business vulnerabilities, but also because in today’s increasingly connected world, a successful infiltration from a cybercriminal could shut down a plant’s operations or start making equipment produce faulty products without the knowledge of managers. Despite the associated benefits of increased connectivity, industrial organisations cannot ignore the fact that more connection points in a modern industrial network architecture increase security risks. It is essential for industrial security programmes to start with a security assessment to identify risk areas and potential threats. This allows organisations to plan a defense-in-depth security approach that establishes multiple layers of defense to ensure data security, whilst benefiting from increased connectivity.

Embracing modernisation and looking ahead

In this age of innovation, it is important to consider how operations and information processing will progress. Therefore it is key that an organisations’ industrial network infrastructure addresses current needs while also anticipating those of the future. Incorporating remote access into operations requires a business’ network architecture that supports video and other collaboration tools. As well as this, integrating mobile devices will require that the network supports tablet authentication and encryption. Workforce changes also should be considered as a modern industrial IP network infrastructure combined with a smart production approach will have a significant impact on manufacturing employees. It requires IT and OT professionals to have a full understanding of the converged environment, and will reshape roles for those responsible for developing and overseeing it.

Modern manufacturing networks are digitising and transforming nearly every aspect of industrial operations. Plants and systems that previously operated in isolation can be integrated with end-to-end connectivity and machines that had little or no visibility into their performance can now be monitored in real time. Workers who were once reliant on manually collected data can utilise production intelligence, online support and mobile collaboration to make better decisions. Modern network systems play an essential role in conceptualising these changes, whilst addressing potential future challenges and anticipating future innovations and growth.