Spatial Computing has the power to optimise factories of the future and give us more frontline control according to one of the world’s leading IoT specialists.

PTC’s Valentin Heun has been leading the company’s research and development work in this area and believes it’s the purest form yet of blending technology into the real world, giving engineers, designers, programmers and company bosses the opportunity to improve workflow, productivity and encourage closer human and robot collaboration.

The VP of Innovation Engineering feels that being able to bring the digital and physical world together in a way that harnesses the power of rapidly improving human user interfaces implemented with augmented reality can unlock a myriad of industrial issues on the shop floor.

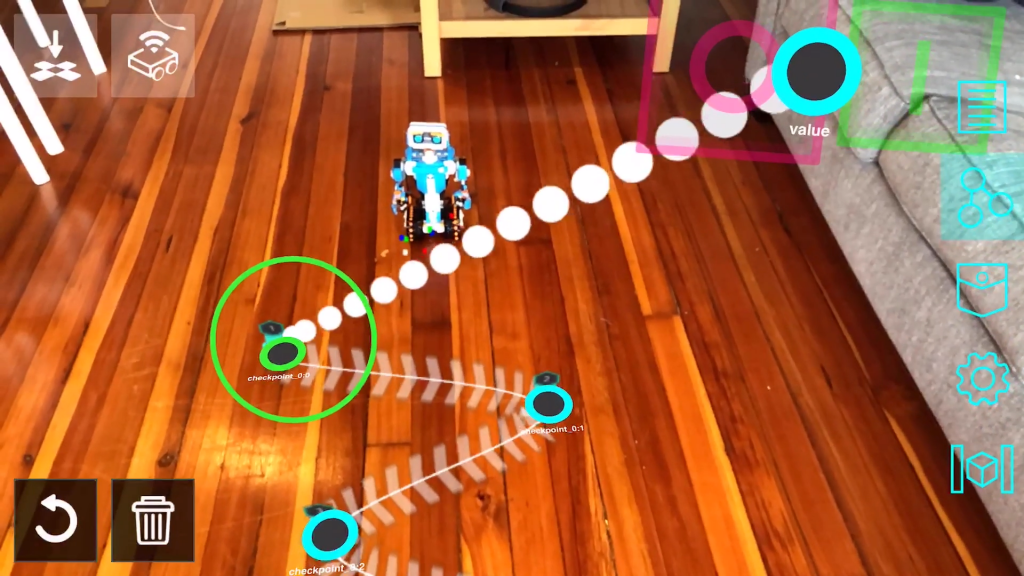

His company has launched Vuforia® Spatial Toolbox, an open source product that aims to accelerate Spatial Computing research for innovation labs, and is already attracting a number of collaborators, including the Advanced Manufacturing Research Centre (AMRC) in Sheffield.

“Spatial Computing might seem like a million miles away, but in reality, we are using it every day,” explained Valentin, who joined PTC in 2017 when he co-founded the company’s Reality Laboratory.

“If you’ve ever ordered a taxi through Uber, looked up at a tube station information board to see when the next one is due or used Google maps to find that great restaurant you want to try, then you’re already a user.”

He continued: “What we are trying to do is to take the capabilities of this technology and apply it into the industrial world to see how it can solve some of our most valuable problems. It is a fantastic resource as it allows us to immerse ourselves in a digital world, which, by using the power of AR, VR and sensors, we can position, instruct and understand machines and their impact a lot better.

“For example, leveraging spatial analytics for continuous process improvement can more accurately and readily identify worker and production bottlenecks than manual or paper methods.

“This insight could be critical for reconfiguring production capacity and manufacturing processes to improve labour efficiencies, increase safety and productivity, even introducing new products to market more quickly.”

The impact of Covid-19 was heavily felt in manufacturing, with a number of sites being forced to close or, those that could remain open, having to quickly adapt their operations to ensure social distancing was possible.

Supplier and customer visits were also cancelled, presenting a whole host of logistical issues to contend with, especially if machines went down or robots needed to be reprogrammed.

“Being able to access machines/shop floor remotely was a godsend in these situations and Spatial Computing will only accelerate a firm’s ability to control an increasing amount of its production line from the safety of a self-contained office or home,” added Valentin.

“Improvements in human interfaces and augmented reality also means in-context robotic programming could allow an operator to more simply understand, control and plan its movements for new tasks, with minimal downtime and without specialised outside engineering knowledge.”

He concluded: “We are not at a stage yet where our comprehensive vision of Spatial Computing is ready to hit the shop floor, but our toolbox is accelerating its development and we are seeing more organisations get involved with our software to look at how they adopt it. “I have no doubt it will start to become part of the industrial innovation portfolio within the next two years, so manufacturers should consider looking now at ways in which they can take advantage of it in their factories.”