The 2021.2 Version of the hyperMILL® CAD/CAM suite provides ease of use, improved machining strategies and a range of options for data communication. The latest version leads the way when it comes to programming and machining (from 2.5D to 5-axis simultaneous). It has also supported additive manufacturing for a long time, and with the new version, the advancement of additive manufacturing continues even further.

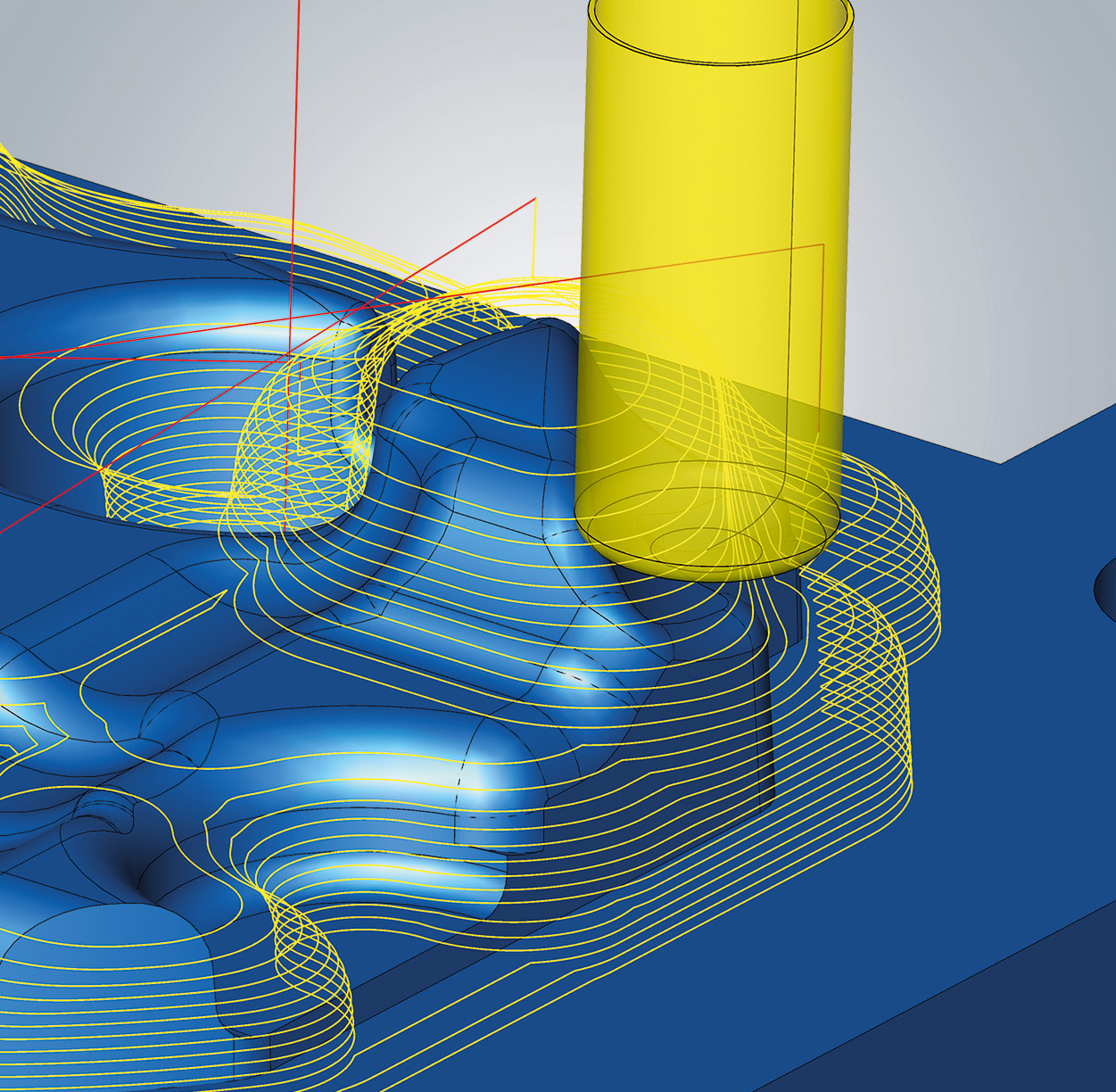

Several new features in Version 2021.2 enhance machining when finishing 3D shapes. For example, the sorting of toolpaths has been optimised, reducing retractions and creating more homogeneous toolpaths. Additionally, the ‘Smooth overlap’ function allows toolpaths to overlap beyond their boundaries, this ensures transition-free machining. The ‘Trim toolpath to stock’ option avoids unnecessary toolpaths, and a free tool geometry can now also be used for the calculation and simulation of toolpaths.

NC code-based machine simulation

hyperMILL® VIRTUAL Machining enables simulation and analysis with maximum precision, as it works with the real NC codes. Two of the most important enhancements in Version 2021.2 are that violations of the axis limitations are detected, and movement sequences are optimised accordingly. To do this, the Optimizer tool can break G1 toolpaths, find a new mate within the axis limits, and continue machining. Here, the approach and retract movements are smoothly linked to the toolpaths and checked for collisions. This ensures that the axis limits are not overrun.

CAM for 3D printing

hyperMILL® is the CAM system of choice when it comes to convenient and reliable programming of additive manufacturing. hyperMILL® ADDITIVE Manufacturing has been extended to include ‘Weave mode’ in the current release. Here, a toolpath in a wave-shape or zigzag movement is generated to apply material to contours or fill areas. This allows the application area to be widened and the thickness to be increased for the individual application movement. The continuous application also improves the metallurgical properties of the applied material. The rework machining of additively manufactured components is an important application of the new hyperMILL® Best Fit function.

Component alignment at the touch of a button

OPEN MIND is revolutionising work preparation in machining operations with hyperMILL® BEST FIT. Instead of having to manually align the stock in the clamping to the NC program, the hyperMILL® CAM system aligns the NC program automatically to the component position. The new function takes full advantage of the options offered by the virtual machine in the CAM program and communication with a 5-axis machining centre using 3D measurements to eliminate the uncertainty that comes with manual alignment.

CAD for CAM users

With hyperCAD®-S, OPEN MIND provides its own CAD program in its product suite that is tailored to the needs of CAM programmers. Important innovations include additional file formats for import and export. The new hyperCAD®-S- version offers three additional formats for file imports: SAT as standard ACIS text and OBJ and 3MF for importing mesh data.

The creation of electrodes has been improved by the optimised selection of the raw material and the hyperCAD®-S Electrode Converter can be used to create import files for the following eroding machines or software. This includes Exoprog (Exeron), Alphamoduli (Zimmer & Kreim), PowerSpark Editor and Multiprog (OPS-INGERSOLL).

Greater Insight

A small but subtle change is provided by the visualisation options. For example, the used stock can be made visible for each job via the shortcut menu. Also, the display of entities used in a job, such as curves, faces or points, can now be switched on and off simply at the touch of a button when the entities are selected.