Speed, efficiency, and accuracy are buzz words often used within electronics manufacturing. Advanced robotic technology is helping companies to achieve these production goals. One company leading the way in soldering systems is Altus Group’s partner, Promation USA with the launch of the new Panda 500 Series.

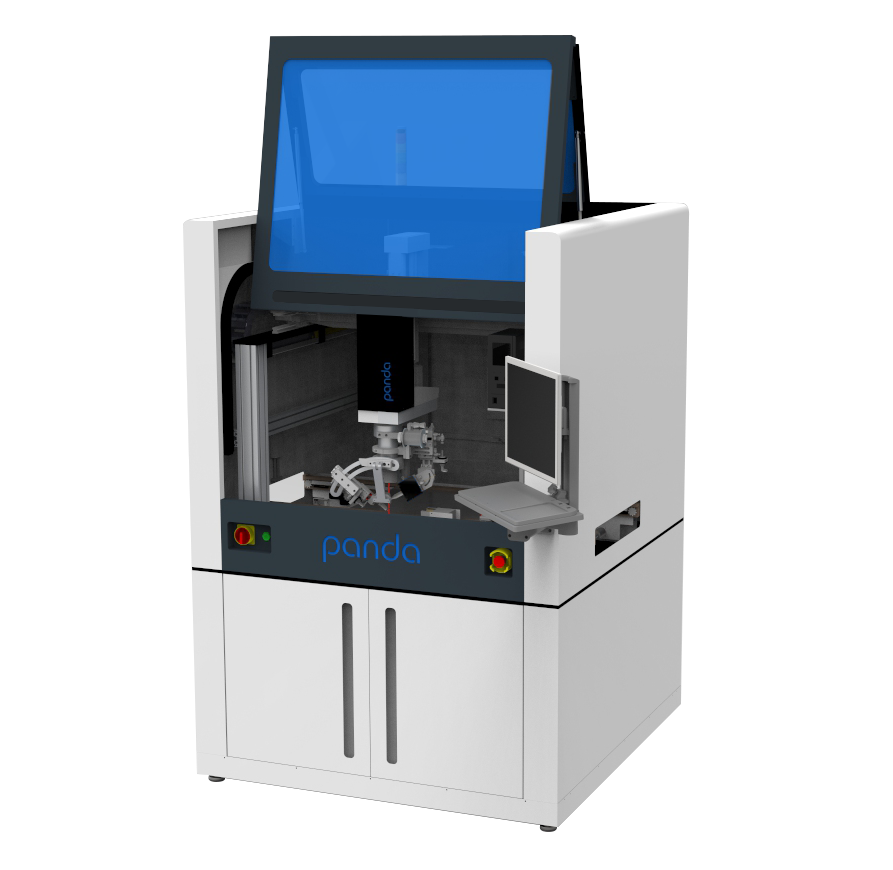

The Panda 500 Series Intelligent Robotic Soldering Platform is designed for manufacturers seeking a high performance PC based in-line soldering system. Recently launched, the system is already receiving attention from Altus’ customers and several early orders.

“The robotic soldering momentum has been building here in the UK and Ireland, with many successful installations since we partnered with Promation USA several years ago,” said Joe Booth, Altus CEO.

“Things will be going up a notch with the launch of the brand-new Panda 500 Series. It is the most technologically advanced robotic soldering system on the market and incorporates much of the customer feedback over the last years and focuses on upcoming trends in electronics manufacturing taking this proven production process to a new level.

“This unit is PC based, with vision assisted programming, barcode reading and automatic barcode driven program selection. It also includes fiducial recognition and keymark capabilities to control production risk and ensure the same high quality soldering every time. These new functionalities come alongside the all-important networkability and data export for traceability which many customers in the UK and Ireland have been requesting to support their high-tech, high value production requirements.

“The Panda 500 will be a game changer for many of our customers and we are looking forward to introducing it to our network of clients in the coming months as our first unit arrives soon.”

Following two years of research, the Panda 500 robotic soldering system has been designed with a number of key features to assist electronics manufacturers. It has a 500mm x 500mm working area and is equipped with the same proven 180W power supply and N2 at tip and range feeding mechanisms. It also includes a new robotic end-effector design that uses dual articulating arms that mimic the human hand’s dexterity. This allows the soldering iron or solder material to be removed independently from each another.

For further information contact Altus Group www.altusgroup.co.uk.