Winner of the France 2030 ‘Hydrogen technology brick’ call for projects, Hutchinson is launching the OBI-1 project to accelerate the industrial development of fuel cells.

The aim of this ambitious project is to develop innovative and cost-effective bipolar plates for new-generation fuel cells. Thanks to Hutchinson’s materials expertise, OBI-1 promises to reduce manufacturing costs, improve performance and reduce the carbon footprint of fuel cells, thereby accelerating the transition to clean, sustainable energy systems.

Hutchinson was already a pioneer in the hydrogen sector, producing the envelopes for the Astra-Torrès airships back in 1911. Expert in the design and production of technical products in rubber, thermoplastics, composites and metals, Hutchinson is now tackling the challenges of hydrogen growth and industrialization.

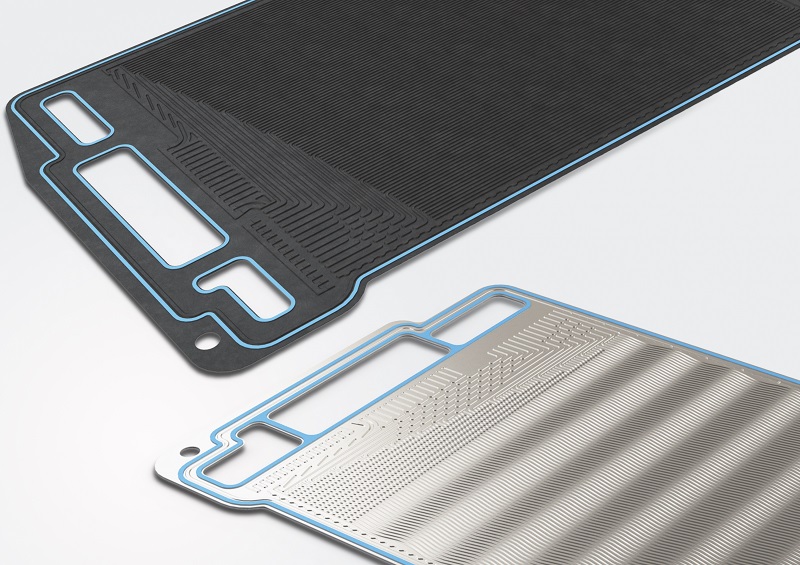

Fuel cells use hydrogen to produce electricity. At the core of these devices are the bipolar plates, which are essential for the electrochemical processes by facilitating the distribution of gases, the conduction of electrical currents, and the thermal management of the cell. These plates significantly impact the efficiency, durability, and cost of fuel cells, thereby influencing their large-scale adoption.

Provide all fuel cell manufacturers with new-generation bipolar plates that are more efficient and cost-effective The OBI-1 project aims to develop a new generation of bipolar plates with sealing to improve fuel cell performance, reduce their carbon footprint and significantly cut their cost. Hutchinson will develop two technologies: Composite plate with a new material and manufacturing process, Metal plate with an integrated sealing system and an optimized manufacturing process (very thin

sheet in mass production).

Hutchinson’s expertise in materials and design dedicated to advancing hydrogen technology Launched in July 2024, the project will run until early 2028. Over a period of 43 months, experts from the Research and Innovation Centre and teams of the Precision Sealing Systems Activity will focus on the research and development of new materials for composite and metallic bipolar plates, assembly technologies and associated sealing systems.

The work will be aimed at improving transverse conductivity, enhancing corrosion resistance, and perfecting elastomeric sealing with low chemical release. The project also includes

validation under representative conditions and the transition to mass production.

“We are proud to be launching the OBI-1 project with the support of ADEME. This project represents a crucial step in our commitment to cleaner, more sustainable energy use,” says Brice Gabrielle, Hydrogen R&D Project Coordinator.

By the end of the project, Hutchinson will be able to offer bipolar plate solutions with integrated sealing systems:

√ Increased compactness to create smaller stacks or generate more power for the same footprint, improved functional performance and simplified stack assembly.

√ Large-scale production in France to maintain French leadership in H2 technology.

Meet Hutchinson at Hyvolution Paris, world’s leading H2 event from 28 to 30 January 2025, Booth n°4N84 | Hall 4.

This project was funded by the French State as part of France 2030 operated by ADEME.