HPC KAESER compressed air equipment is renowned for its longevity. But why does it last so long?

A customer rang HPC recently to enquire about replacing his HPC KAESER SK25 rotary screw compressor. “It hasn’t missed a beat” for 38 years, he told us, and it was still running with its original motor and airend.

This is by no means unusual.

Many of our customers are still running the same compressor they bought 25+ years ago – and frequently with original components.

The reason? We believe in compressed air equipment that is built to last.

Some compressed air equipment brands appeal to customers because they are the cheaper option. But a few years down the road, customers find they are forced to replace their equipment, not least because it can’t be repaired.

We don’t subscribe to planned obsolescence. And we don’t believe in doing things on the cheap.

What makes a compressor last

HPC KAESER compressors are known for quality, reliability and longevity.

So why do they last as long as they do?

We ensure good engineering practice:

- Our brilliant functional designs stand up in a variety of less-than-ideal conditions.

- We don’t skimp on materials, only ever using quality components.

- We don’t believe in taking short cuts that will have a detrimental effect on a machine’s lifetime and reliability.

- And, we have a specialist UK network of highly trained engineers that ensure prompt efficient service is always at hand.

Let’s dig a bit deeper into the keys elements of a compressed air system, and highlight the choices HPC KAESER makes:

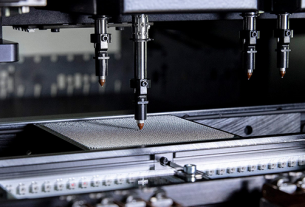

1. Rotary Screw Compressors.

Airend: Our airends are large, manufactured with close tolerances with precision ground rotors. They operate at low temperatures and low running speeds. The design is simple, they rarely need replacing, but are straightforward to replace when they do.

Motor: Made by Siemens, a renowned manufacturer of quality high efficiency motors, they run at low operating speeds, monitored by highly accurate temperature and electrical current sensors.

Coolers: We oversize for the harshest of environments and working conditions. Our coolers have superior fan cooling to ensure maximum cooling air flow with the minimum of power required. Reliable mechanical or electronic thermostats ensure optimum temperature control, reducing stress across components and lubrication.

Piping: With minimum oil leaks, HPC KAESER machines are built with as much rigid piping as possible. To reduce energy losses, the piping design is minimised and incorporates swept bends to reduce pressure loss inefficiencies.

Valves: Large in size, they ensure adequate air flows, and are quality built for long term reliability.

Frame and panels: We only use high quality materials, which are corrosion proofed by superior painting and powder coating. Using heavy plate material and solid fixings provides durability. Superior durable materials are used for sound insulation.

2. Air Treatment and condensate

Refrigeration dryers: Many of our quality-built refrigeration dryers are thermal mass, storing cold energy so that both refrigeration compressor and fan(s) can switch off when not required, saving both energy and increasing the life of these expensive components.

Adsorption dryers: Our quality-built dryers are designed to withstand harsh environments, have minimal pressure and purge air losses, and operate at low temperatures, increasing the length of their life.

Condensate – Zero loss drains – oil water separator. These are solidly constructed, built with quality robust electronics, have minimal moving parts, and excellent sensor activation.

3. Selection, Installation and Maintenance

Correct Sizing and Control. Your HPC KAESER Compressed Air System will be specified to meet your exact requirements. We ensure the best equipment is selected, considering the pressure, volume of air and air quality requirements. Lastly, using the Sigma Air Manager (SAM4.0) we ensure that the Compressed Air System is controlled correctly, from an efficiency point of view, and with a calm control methodology.

Service and maintenance. All service engineers, whether they are employed by HPC or an HPC Authorised Distributor, are fully certified after undergoing an extensive HPC Service Engineer Training Program. This ensures they are safe to work and are uniquely qualified to service and maintain HPC KAESER compressed air equipment.

It’s not just a tagline. HPC KAESER compressors are designed from the start to deliver the air you need for years and years to come.

About HPC and KAESER

HPC and KAESER’s partnership has spanned over four decades and two generations of family involvement. The partnership stands for mutual trust, a shared belief in world-class manufacturing technologies and a commitment to applying this partnership approach to our customer relationships. The spirit of the HPC KAESER partnership is repeated with a network of HPC Authorised Distributors and in all the company’s customer relationships.

Contact Details

Tel: 0845 430 0472

Email: info@hpcplc.co.uk

Web: www.hpccompressors.co.uk