Simon Francis, group quality director of G&P, discusses the critical role of quality management in decarbonising the manufacturing industry, explaining how ‘zero-defect’ ambitions can drive sustainability without compromising operational and financial performance.

In June 2025, the UK government published its Advanced Manufacturing Sector Plan[1] as part of the wider Modern Industrial Strategy[2]. The policy paper was developed to position the UK’s manufacturing sector at the forefront of global economic competition and security, while subsequently helping to accelerate towards net zero and clean energy goals.

To align with the government’s rejuvenated approach to sustainable manufacturing and supply chains, manufacturers are increasingly seeking new ways to decarbonise without compromising performance or cost. Indeed, managing sustainability with economic growth can often be viewed as a difficult balancing act when, in reality, they usually go hand in hand.

Reducing waste, improving energy efficiency and eliminating unnecessary material consumption – all key tenets of sustainable manufacturing – are perfect examples of decarbonisation pathways that also provide long-term financial benefits.

One process that has a central, but sometimes untapped, role to play in decarbonising manufacturing supply chains is quality management. However, by reducing process variation and improving product conformity, it’s safe to suggest that effective quality systems are proving to be one of the most powerful enablers of sustainable manufacturing.

Why focus on quality?

At its core, quality management is about doing things right first time. It fundamentally exists to eliminate errors, rework, alleviate waste forms and ensure consistency. In high-value sectors, such as automotive, aerospace and defence, even small defects can lead to a significant waste of correction incurring unnecessary consumption of additional resources, materials and energy. By embedding quality early and consistently across the manufacturing supply chain, companies can prevent the need for activities that consume resources without adding value and can achieve operational, financial and sustainable benefits.

The advantages of operational excellence have been particularly visible in the UK automotive sector. According to data from the Society of Motor Manufacturers and Traders (SMMT), UK vehicle manufacturers have reduced CO₂ emissions per vehicle by 61% since 1999, while also cutting water use per vehicle by around 47%[3].

Even more impressively, in 2024 less than 1% of residual material generated by automotive manufacturing was sent to landfill. These improvements were not the result of a single sustainability initiative, but of widespread adoption of lean manufacturing, process control and quality discipline, supported by strong Quality Management Systems.

Similarly for the aerospace and defence sectors, quality management systems require organisations to take a risk management approach to quality and integrate supplier oversight, process monitoring and corrective action frameworks into their operations. In doing so, these frameworks help firms reduce non-conformance rates, avoid excessive inventory and prevent the need for high carbon logistics or remanufacture.[4]

The role of Industry 4.0 in quality management

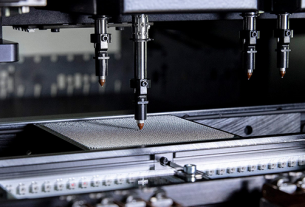

Digital technologies like AI, the internet of things (IoT) and virtual reality (VR) are helping accelerate the shift towards zero-defects. Real-time quality analytics platforms, IoT sensors and machine learning are enabling earlier detection of process anomalies and quality drift. These systems give manufacturers the ability to intervene before defects are produced and prevent unnecessary resource use.

Predictive analytics, another data-driven application, can identify the likelihood of future outcomes, reduce unplanned downtime and ensure optimal efficiency. High-speed, AI-supported vision inspection systems, like those utilised by G&P, further support quality control by detecting non-conformities at high levels of reliability and repeatability, reducing the likelihood of defective parts progressing further down the value chain.

Manufacturers are increasingly using digital twin models and virtual manufacturing tools to optimise assembly processes before physical production even begins, improving factory efficiency and reducing both emissions and costs associated with wasteful operations.

However, technology alone is not enough. Without clear operating procedures and defined quality checkpoints, even the most advanced technologies can quickly become ineffective. True gains are made when quality thinking becomes embedded across the product lifecycle, from product design engineering, through supplier development, into a manufacturing process and finally through lessons learned from warranty.

Putting it into practice

At G&P, our own experience reinforces the need to embed quality throughout the product lifecycle. Through engineering, inspection and supplier development services, we support manufacturers in preventing the creation of defects or by efficiently controlling and reworking non-conforming products, preventing costs and carbon content associated with the additional materials, inventory, production and transport needed to replace them.

Our QTrak platform provides real-time visibility of inspection results, defect trends and supplier quality, enabling early intervention and data-driven decision-making. We also help to stabilise quality upstream through engineering support, reducing the flow of NOK parts into customers.

Where NOK components cannot be reworked, G&P’s deconstruction service provides efficient dismantling and recycling of sub-components. This enables manufacturers to accurately segregate materials and maximise resource recovery while minimising landfill disposal.

The sustainability benefits of this full-pipeline approach are measurable. Manufacturers working with a trusted quality partner can reduce scrap and rework activities, resulting in not just cost savings but significant reductions in energy and raw material consumption. When applied consistently across suppliers and production lines, these savings can scale rapidly, reinforcing sustainability as an outcome of operational excellence.

The future of sustainable manufacturing

As UK manufacturers increasingly pursue low-carbon strategies, the role of quality mustn’t be understated. It’s not simply a compliance exercise, but a strategic solution to enable resource efficiency, reduce waste, enhance reliability and deliver lasting value. Government policy may provide the external motivation, and digital tools the means, but quality management provides a framework help bring these strategies to fruition.

For manufacturers looking to embed sustainability at the core of their operations, now is the time to assess whether the right quality systems, tools and expertise are in place. Partnering with a trusted quality management specialist can provide the independent perspective, technical capability and data-driven strategies needed to accelerate progress – turning quality into a powerful driver of long-term, sustainable growth.

For more information about G&P and its drive towards zero defects through best-in-class quality management solutions, visit www.gpqm.com.

[1]https://assets.publishing.service.gov.uk/media/6858622776eec44bf9d71dcf/industrial_strategy_advanced_manufacturing_sector_plan.pdf

[2] https://assets.publishing.service.gov.uk/media/68595e56db8e139f95652dc6/industrial_strategy_policy_paper.pdf

[3] https://smmtweb.lon1.cdn.digitaloceanspaces.com/wp-content/uploads/2025/07/2025-SMMT-Automotive-Sustainability-Report.pdf

[4] https://msmatter.co.uk/sustainability-esg-and-the-future-of-risk-management-under-as9100/