| Innovative components for lightweight and collaborative robots For maximum load-carrying capacity and rigidity: XZU conical thrust cage needle roller bearing and RTWH gearbox from Schaeffler |

- Schaeffler develops new market with major growth potential

- New XZU conical thrust cage needle roller bearing for robot and cobot joints: 20 per cent less friction and 30 per cent greater rigidity

- New RTWH precision gearbox for compact design envelope

Today’s advanced automation and production facilities need lightweight robots (LWRs) and collaborative robots (cobots) that are highly dynamic and accurate. Drawing on its many years of experience in industrial automation, Schaeffler has developed two new and highly innovative components for LWRs and cobots, with which it is opening up new opportunities in a fast-growing market segment.

The new XZU conical thrust cage needle roller bearing is used both as an articulated arm bearing in LWRs and cobots and as the main bearing support for the company’s new RTWH precision gearbox. This combination of RTWH gearbox and XZU bearing ensures the most compact design envelope and the greatest rigidity possible in applications.

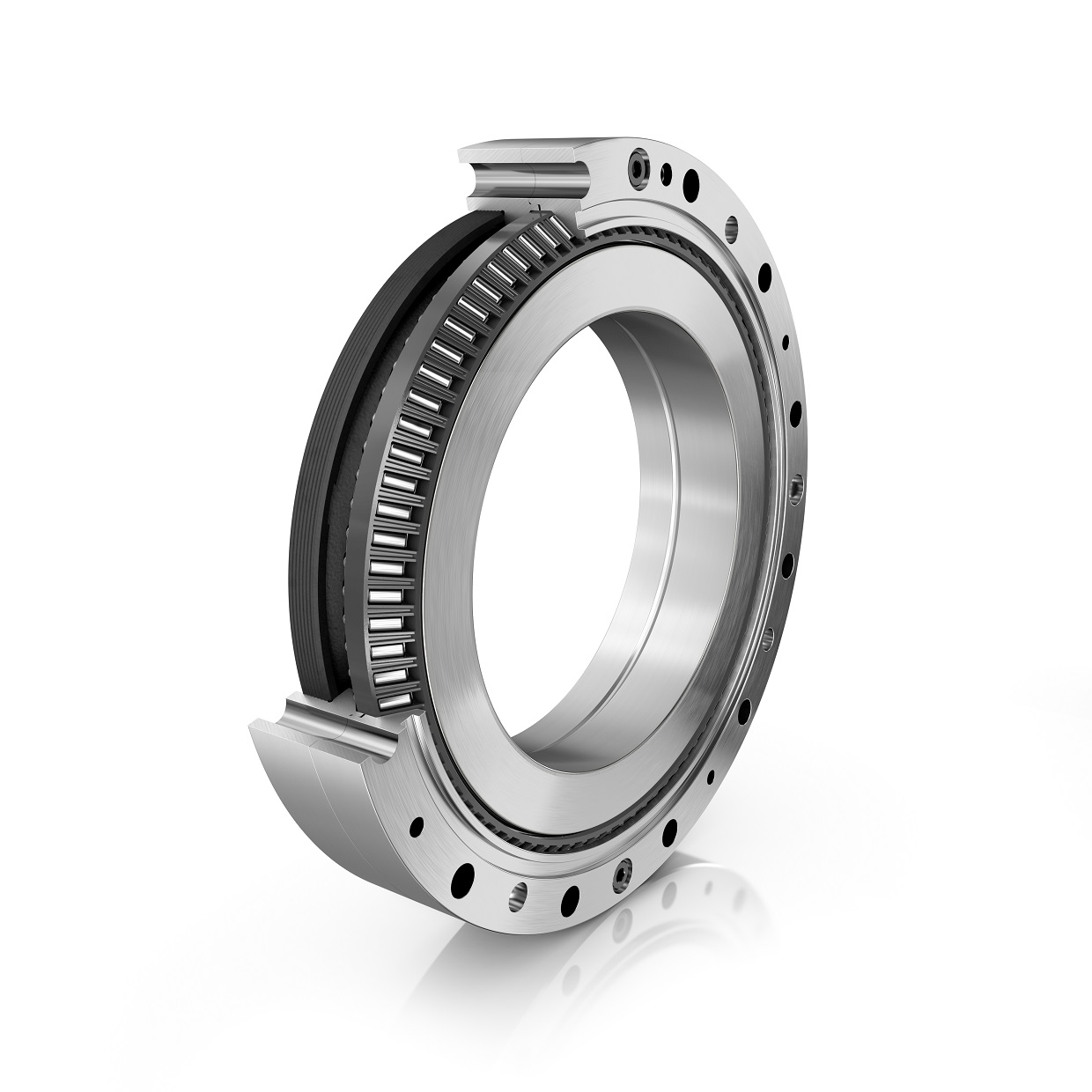

XZU

conical thrust cage needle roller bearing for articulated-arm bearing supports

Schaeffler’s double-row conical thrust cage needle

roller bearing is the culmination of 70 years of experience in the design and

manufacture of needle roller bearings. The main benefit of the bearing for

customers is that it has more load-bearing rolling elements than the crossed

roller bearings currently used for articulated-arm bearing supports, while

maintaining the same design envelope. Customers therefore have the option of

using smaller-sized bearings, thereby saving on space and weight – major benefits

when it comes to downsizing. This opens up new opportunities and possibilities

in the development of LWRs and cobots. The bearing technology spawns a

constantly growing array of new applications for users.

Apart from more load-bearing rolling elements, the XZU unit’s X-arrangement of needle rollers in two raceways offers support distances that, depending on installed size, increases rigidity by at least 30 per cent compared to crossed roller bearings. Furthermore, by housing the rolling elements in cage guides and having them configured in two raceways instead of just one, the XZU delivers a 20 per cent reduction in friction.

For customers, this all translates into more precise movement and less overshoot on reaching the end position. Overall, applications using these bearings require fewer control processes and can operate at higher speeds, thereby making the production cycle in question much more efficient.

RTWH

precision gearbox – silk hat-type speed reducer

Schaeffler offers ready-to-install, silk hat-type

speed-reduction gears – or “speed reducers” as they are also known – for use in

robot articulated joints. By harnessing the functional principles of strain

wave gearing, the RTWH combines high gear ratios – and correspondingly high

torques – with relatively lightweight construction. The RTWH precision gearbox

developed by Schaeffler is characterised by clearance-free operation, high

positioning accuracy, and compactness. It is also very durable and therefore

has a long operating life.

A long operating life is a key factor in robots, which need to operate with maximum reliability and minimum downtime. Depending on their size, Schaeffler’s RTWH gearboxes can deliver reduction ratios of 50:1 to 150:1. The torques resulting from these reductions are transmitted reliably and accurately due to the gearbox’s robust construction and the integration of the highly rigid XZU conical thrust cage needle roller bearing. As a result, robots fitted with RTWH gearboxes are highly efficient and able to move through to their end positions dynamically, accurately, and without excessive overshoot. This means they are able to complete sorting, handling and assembly tasks quickly and efficiently.

Another stand-out feature of the new precision gearbox from Schaeffler is its compact and maintenance-free design. It is available in all standard sizes. The drive flange is a hollow shaft and can be factory-tailored to the customer’s requirements.