The electronics industry is always looking for faster, better and cheaper manufacturing techniques. Central to progressing this ideal in the future will be Artificial Intelligence (AI), a core element of the Industry 4.0 revolution. To ensure they are ready and at the forefront of this technology transformation, Altus Group, a leading distributor of capital equipment in the UK and Ireland, has a number of highly advanced applications which have been designed to covert data into information that will benefit the industry.

Leading the way in this advancing drive forward is Koh Young, an innovative equipment provider who are enabling the Smart factory of the future by adopting AI to generate ‘knowledge’ from ‘experience’.

Richard

Booth, Altus Group CEO said: “Much of our market

knows that Koh Young is an outright leader in the inspection market having sold

more than 15,000 systems globally. They are a true disruptor in PCBA Inspection

Technology offering the only fully 3D light measurement device for AOI and SPI.

People will also understand that the real value of inspection is the process

improvement value add, and the informed decisions that can be made by utilising

the measurement content collected.

“Many people talk about machine learning,

machine to machine communication and back propagation. Koh Young is paving the

way with highly innovative systems that address AI and give manufacturers the

opportunity to advance their processes making them ‘Smarter’.”

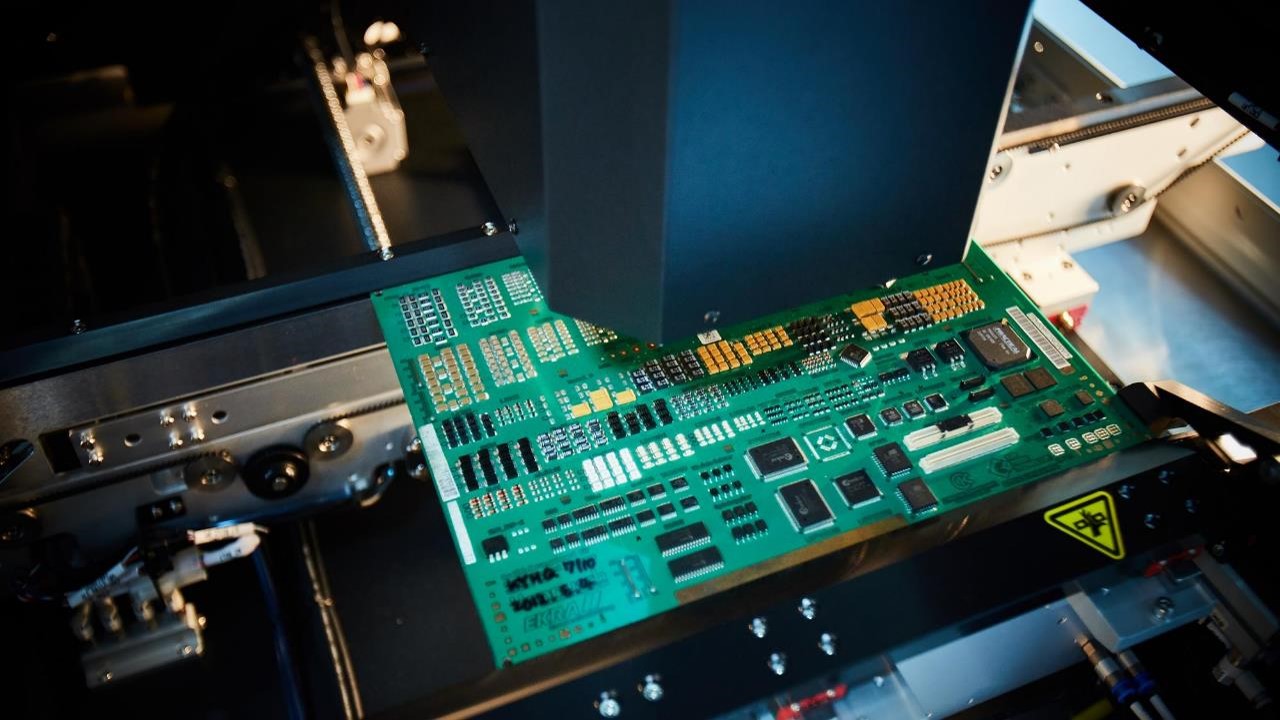

AI implies that such improvements can be fulfilled quicker with machines that continuously learn to solve new problems. However, the main challenge is complete end-to end optimisation. Harnessing the power of its own AI solution, Koh Young has developed Koh Young Process Optimizer (KPO) solution.

KPO is the Koh Young smart factory solution driven by AI to control and optimize the printing and mounting operations. KPO heavily relies on accurate 3D measurements data and error detection from SPI and AOI machines, which sets the stage for smart factory solutions. The KPO printing solution includes three interlinking modules that exercise complex algorithms to develop closed-loop print process recommendations. The enhanced AI engine actively optimizes the printing process by combining real-time printing and SPI measurement data.

Altus has a team of experts, proficient in Koh Young technology, including the KPO solution, and can offer advice on the systems. Customers can understand the full capacity of Koh Young equipment through live data and real-time demonstrations shared over a VPN network. For more information on how Koh Young and their approach to AI can lift production performance contact Altus.