Bindatex, the UK’s leading provider of specialist process and cutting services is pleased to announce it has been awarded an Innovate UK grant of almost £100,000 from the Sustainable Innovation Fund. The purpose of the grant is to support a critical six-month R&D project to further develop and upscale their highly innovative 1mm wide slitting capability for next generation composite parts manufacturing technology.

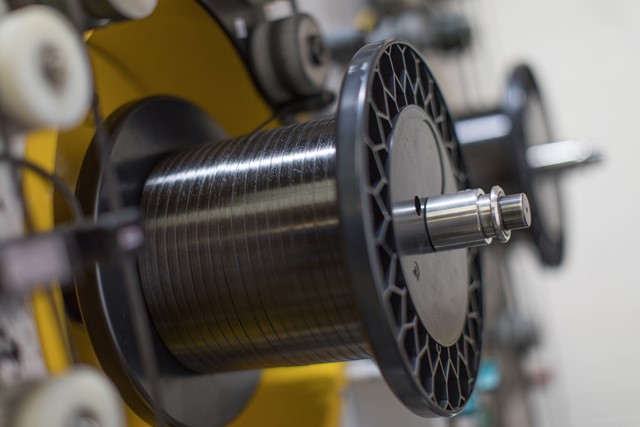

Bindatex Advanced Material cutting are world leaders in the precision slitting of carbon fibre to widths as narrow as 1mm.

The funding will support extensive research and testing and development of bespoke technology to enable Bindatex to produce 1mm wide thermoplastic UD slit tape in volumes that meet the future growth demands of light weight aircraft manufacturers and other key transport applications. The Innovate funding will be pivotal in enabling Bindatex to maintain its position at the forefront of technical slitting to support companies who are developing their digital composites printing solutions worldwide.

Chris Lever, Bindatex’s managing director said: “I cannot stress how beneficial this grant from Innovate UK is to the continuing growth of Bindatex. It’s going to allow us to carry out research that would not otherwise be possible at the current time due to the impact of Covid.

“The past seven months have not been easy; however, we have continued to invest in key initiatives including our Industry 4.0 data capture system. This investment has helped us to adapt to different markets, whilst still maintaining the high level of service and fast turnaround times our customers rightly expect. This Innovate UK funding will give us an even greater capability and open up more potential markets to Bindatex, making us a much more resilient UK enterprise as a result.”

One of the objectives of the projects is to increase the yields of ultra-narrow slitting and reduce any in-process waste being sent to landfill as this is not currently sustainable at increased volumes. The aim, as manufacturing capability is ramped up, is to identify how this waste can be recycled and reused for other processes.

Lever said: “There is strong demand right now for digital composite printing to replace small metallic parts on aircraft, cars, rail and possibly medical technology too. The market potential is huge.”

Innovate UK, as part of UK Research and Innovation, is investing up to £191 million to fund single and collaborative research and development projects as part of the Sustainable Innovation Fund over the next two years. The aim of these competitions is to help all sectors of the UK rebuild after the effects of COVID-19.

The Sustainable Innovation Fund is funding 1,103 projects, 1,189 UK businesses and totalling over £130 million in support across the UK.

Innovate UK Executive Chair, Dr Ian Campbell said: “In these difficult times we have seen the best of British business innovation. The pandemic is not just a health emergency but one that impacts society and the economy.

“Along with every initiative Innovate UK has supported through this fund, with this project Bindatex Advanced Material Cutting is taking an important step forward in driving sustainable economic development. Each project is also helping to realise the ambitions of hard-working people.”

Bindatex reconfigured its business in March in the wake of a Government call for manufacturers to contribute to the fight against the Coronavirus. It was able to change its production systems to die cut disks for filters for the manufacture of ventilators for the NHS.

To find out more about Bindatex’s full range of capabilities, visit https://bindatex.com/