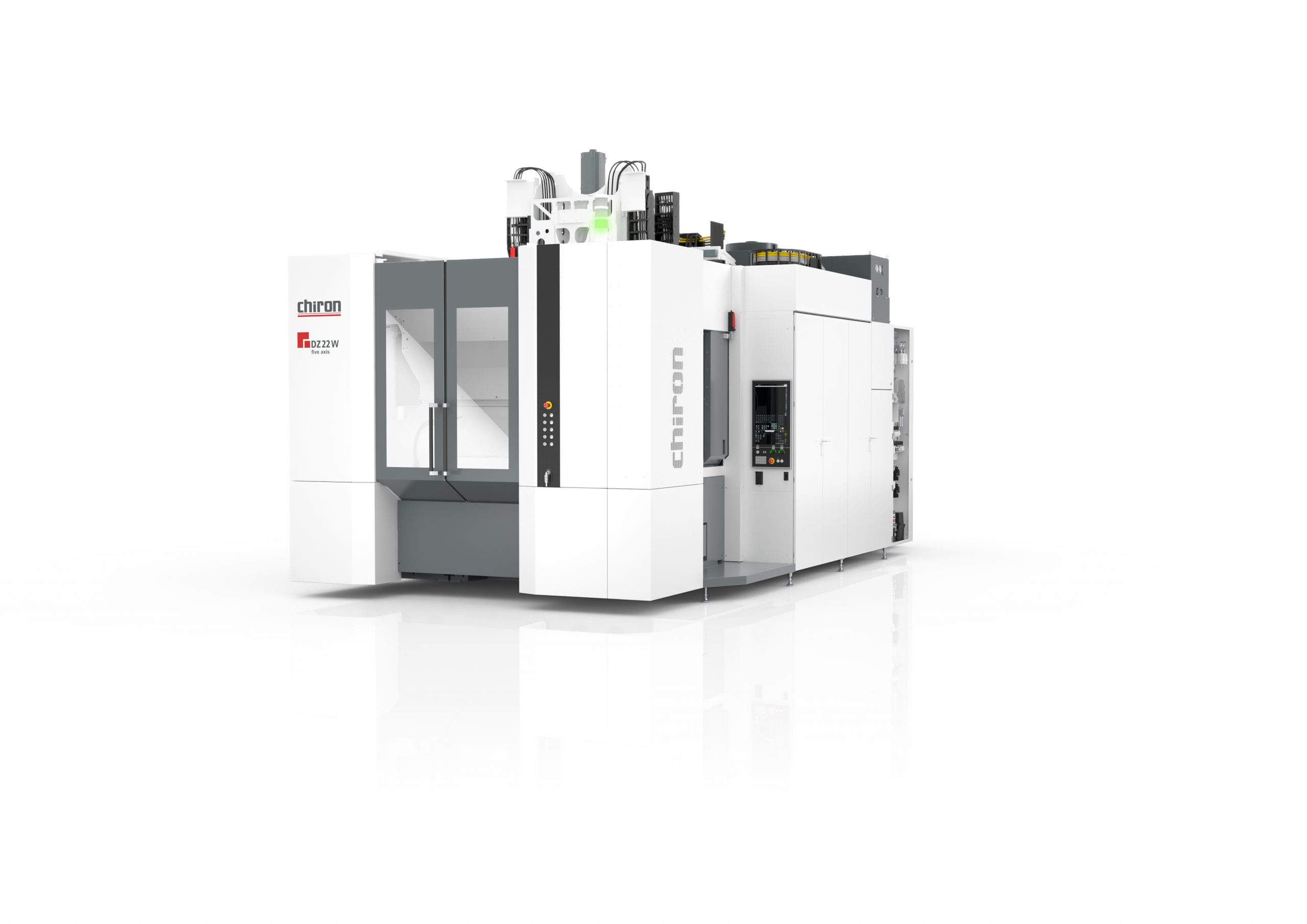

To meet the criteria of ever-expanding customer demands, CHIRON has now launched its latest machining centre, the new 5-axis CHIRON DZ22W. Based upon the proven platform of the existing 16 Series, the new CHIRON DZ22W that is available in the UK from the Engineering Technology Group (ETG) has been introduced to meet the exact needs of the industry.

The new CHIRON 22 Series boasts precise, dynamic machining, high technical availability and is particularly impressive in the complete machining of large steel and aluminium components, such as electric motor and transmission housings, oil sumps or chassis components in the automotive sector. Of course, as with all CHIRON machines, the DZ22W 5-axis is a production centre with attributes that extend to manufacturers across all industry sectors. This is a credit to intensive dialogue with multiple market segments that have resulted in a fundamentally new machining platform with an impressive mobile gantry design.

Thanks to this proven moving gantry design, a particularly rigid machine bed and active component cooling, the DZ22W 5-axis achieves a high level of precision even for large components. Short cycle times are effortlessly achieved with high axis acceleration, short changeover times and rapid traverse speeds. The integrated workpiece changing device, which enables blanks and finished parts to be loaded and unloaded during machine operation, further increase productivity.

From a specification standpoint, the new DZ22W 5-axis has a twin-spindle configuration that can simultaneously work at speed in the 620 by 650 by 600mm X, Y and Z-axes work envelope. Within this spacious envelope, customers can load a maximum component size of 599mm diameter with a maximum height of 340mm with a maximum workpiece load of 600kg.

As with all machines from the CHIRON stable, the new DZ22W 5-axis demonstrates industry-leading productivity levels with a colossal 61kW spindle motor capable of reaching speeds up to 20,000rpm. This power and speed are complemented by an axis acceleration rate of 10, 10 and 17m/s2 across the X, Y and Z axes and a rapid feed rate of 75m/min across the three axes. This astounding speed is built into every aspect of the CHIRON 22 Series with a world-leading tool change system that demonstrates chip-to-chip times of just 3.1 seconds.

The two spindles can be specified with a choice of HSK-A63, HSK-A100 or HSK-T63, with each spindle having an individual tool carousel of 77 tools. The two different main spindles can be specified depending on the task – a high-speed spindle for workpieces made from aluminium or aluminium alloys and a high-torque spindle for large tools and hard-to-machine materials. All additional units, such as cooling, hydraulic and extraction systems are integrated into the machine to take up very little space. As with all CHIRON machines, the DZ22W 5-axis is available in different configurations with customers having the facility to choose between a ball screw drive or a linear direct drive. With robot or gantry loaded automation available as well as a multitude of other optional features, now is the time to contact ETG to take your productivity to the next level.