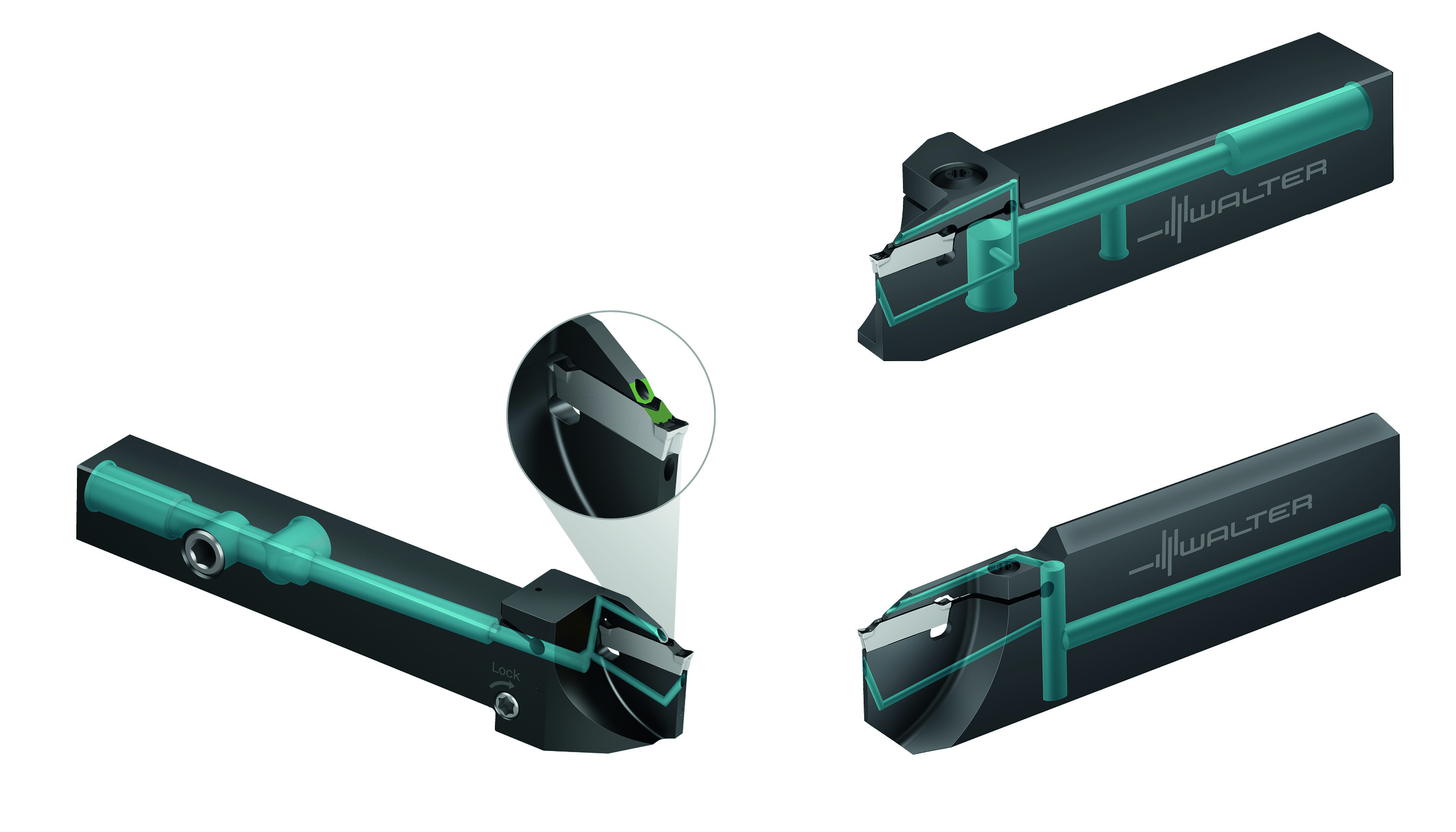

Walter has now expanded its range of parting-off and grooving systems with the arrival of the new G4011-P tool holder and the DX18 grooving inserts. The new G4011-P monoblock shank tool is designed as a universal tool for all common grooving operations and the DX18 inserts provide a double-edged design with a second prism.

With a reinforced shank, the G4041-P parting-off tool has been optimised for deep grooving and parting off operations. Walter has introduced the G4014-P system with the ‘SmartLock’ insert clamp that facilitates easy insert changes from inside the machine – even where space is limited. This makes the G4014-P perfect for use in machine tools where space is limited, such as Swiss-type sliding head lathes and multi-spindle machines. The insert change is simplified by an easy access Torx Plus clamping screw that can be operated from each side of the tool. This results in a time saving of up to 70% during an insert change.

The G4011-P universal monoblock shank tool is available with shank sizes of 10 by 10mm, 12 by 12mm, 16 by 16mm, 20 by 20mm and 25 by 25mm, which makes this exceptional new addition perfect for small compact turning centres as well as larger more robust machine tools. Furthermore, the new clamping design generates 30% higher clamping forces compared to conventional tools whilst the innovative new positive engagement and form-fit design at the rear of the insert improves the precision location of the insert in the tool body. The cutting insert is centred in the seat by a V-guide and this form fit prevents incorrect mounting, reduces vibration and helps to achieve high indexing accuracy.

Perfect for recessing, grooving and parting off, the new G4011-P is available for cutting widths up to 3mm and cutting depths of 10mm and 17.5 mm with a maximum grooving diameter of up to 35mm. The reinforced shank parting blades are available as right-hand, left-hand and contra versions with blade heights of 26mm and 32mm, with a choice of no internal cooling or with precision cooling on the rake and flank face. Walter is offering the G4014-P system with ‘SmartLock’ in shank sizes 10–20 mm. Its qualities make it the current benchmark when it comes to the mass production of small parts.

Concerning the new DX18 grooving insert system, the new inserts are available in widths of 1.5, 2, 2.5 and 3mm and Walter has introduced these insert ranges in its WSM23S, WSM33S, WSM43S and WKP23S grades. This selection of Tiger·tec® Silver PVD grade inserts can maximise productivity and extend tool life on a vast array of material types in the ISO P, M and S ranges, providing complete flexibility for end-users. To further enhance productivity levels, the DX18 is offered in the CE4, CF5, CF6 and GD6 chip formation geometries.

From a benefits perspective, the DX18 can reduce tool change times by 70%, increase clamping forces by 40%, improve chip control through its higher insert profile and the patented form fit groove enhances process security and reliability. When combined with the Tiger.Tec Silver insert grades, the DX18 will undoubtedly improve productivity and reduce costs for end-users.