Dr Stephen Fletcher, Occupational Psychologist and Director at the Occupational Psychology Centre (OPC) shares insights about risk anticipation and how recognising, anticipating and responding to risks better can help improve safety performance.

For over thirty years, the OPC has been a leader in the transport and engineering sectors, with a special interest in why employees make errors and why they may be involved in safety incidents. A recurring theme identified through hundreds of Post-Incident Assessments (PIA) undertaken by their psychologists is poor risk anticipation—a Non-Technical Skill (NTS) shortfall which can be an underlying cause of safety incidents.

Dr. Fletcher said, “Our Post-Incident Assessment work reveals that many employees struggle with risk anticipation and management, which can lead them to have safety incidents. We believe that some of the best employees excel in risk anticipation and risk management, preferring to work at a steady, consistent pace and proactively managing any unnecessary risks.”

OPC psychologists classify risks into three categories:

Personal Risks: E.g., Health and well-being like stress, depression or a bereavement.

Work Risks: E.g., Fatigue, boredom, shift patterns, or new equipment.

Environmental Risks: E.g., Factors like poor weather conditions, distractions or noise.

Dr Fletcher emphasised, “Anticipating and managing risk is essential in manufacturing, automation, and production. Identifying potential risks and implementing measures to control them can significantly enhance workforce safety along with operational efficiency.”

So, what are some key insights for a good personal risk strategy?

Planning for Risks and Dynamic Risk Assessments

Planning for risks is key. Safety-critical workers who conscientiously plan ahead for risks are less likely to encounter an incident. A safety-conscious employee will think ahead to identify hazards along with strategies to avoid them.

While upfront planning is essential, recognising that unexpected events can arise requires dynamic risk assessments too. For example, equipment breakdowns needing immediate attention, bad weather may necessitate loading plan adjustments, or extended maintenance can create production pressures, but safety must always come first.

OPC Psychologists recommend proactive risk assessments before work and dynamic risk assessments during shifts to adjust for unexpected changes.

Recognising Subtle Cumulative Risks

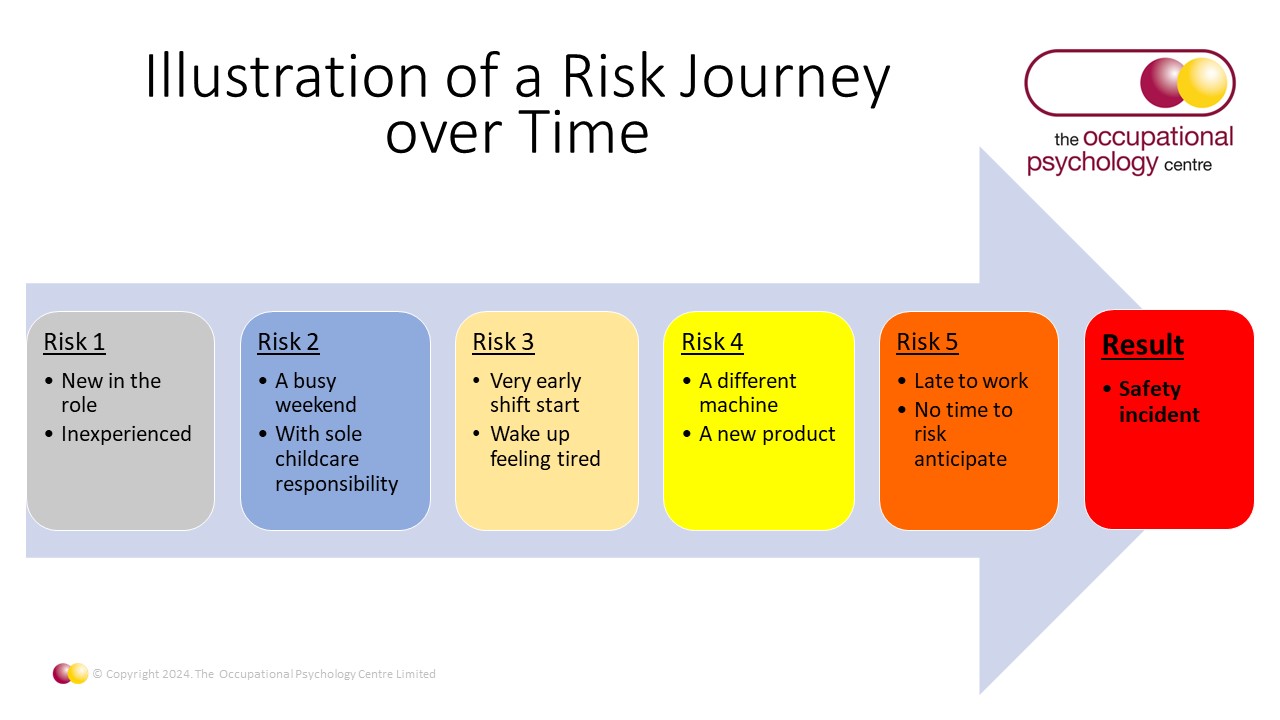

“Subtle, cumulative risks can be more dangerous than overt ones, like a power outage, for example, because they’re less obvious, and they can lead to a more serious incident. Employees often underestimate subtle risks, which can accumulate over time, increasing the probability of an accident—a phenomenon we call a ‘Risk Journey’”, added Dr Fletcher.

Different Risk Profiles

“Employees’ attitudes to risk varies, impacting on workplace safety. Some workers may be inexperienced, others could be complacent from long-term service, and others may deny there are risks or feel vulnerability in acknowledging them. Highly risk-averse employees, who prioritise safety, are ideal for safety-critical roles. Ultimately, our risk-taking propensity can be shaped by individual experience and personality. Recognising these individual differences is crucial for a safe working environment,” said Dr Fletcher.

OPC Recommendations to Help Improve Safety Performance

- Promote effective risk anticipation with your employees e.g. by encouraging them to conduct proactive risk assessments before and during shifts. Post-shift reviews can also help identify near misses or improvements.

- Address risky behaviour promptly by implementing immediate action plans.

- Provide post-incident training to support employees involved in an incident, focusing on risk awareness and management.

- Encourage a safety-reporting culture.

- Incorporate the NTS of Risk Anticipation into recruitment processes.

Psychometric Tools to Help

OPC Assessment offers innovative tools like the Risk and Time Focus Questionnaire (RTQ) to help profile candidates’ risk anticipation, management, and time focus. Additionally, the Safe Personality Questionnaire (SAFEPQ) assesses key factors such as cautiousness, conscientiousness, resilience, and rules focus, which are linked to safe behaviours at work and risk anticipation.

Dr Fletcher concluded “The NTS of Risk Anticipation and Risk Management are crucial for strong safety performance. An employee proactively anticipating, planning, and responding to risks is much less likely to have a safety incident. It’s important to recognise even small risks and their potential to accumulate. Planning for risks is planning for safety!”

If you think the OPC could help support your employees with better risk anticipation then get in touch with our friendly team.

If you think the OPC could help support your employees with better risk anticipation then get in touch with our friendly team.

Tel: +44 (0)1923 234646

Email: admin@theopc.co.uk

Visit: www.theopc.co.uk