With increasing alarms over forest fires across the globe, businesses such as Hart Door Systems have to ensure they develop products that are effective in climate situations wherever they are writes Chris Dobson.

As I write there are intense wild fires in North and South America as well as Europe and other parts of the World causing a massive release of carbon emissions which degrade the air we breathe. It is encouraging to hear that Hart has developed door systems to cope with climate situations. For example Hart developed the Typhoon shutter specifically to withstand Typhoon storms in the Far East. Clearly these shutters will be of great value in any part of the Globe where dramatic storms are experienced.

A particular example is an isolated grain store in England’s Northumberland which was hit by dramatic storms which barrelled their way down a valley and hit a silo with extreme violence. The result was to install Hart’s Typhoon shutters which act as a formidable barrier against future high winds, heavy rain and flying debris.

Hart’s uniqueness in the industrial door manufacturing sector came to fruition through its Speedor, automatic, high speed door. This robustly engineered door, tried and tested vertical high speed door can be used internally or externally to optimise traffic flow, improve working conditions and save energy.

Now in several versions it is Speedor Storm that is getting considerable interest as climate changes. It is not surprising as its fast open and close cycle will deliver maximum environmental control and energy usage reduction. Through its unique design Speedor Storm optimises traffic flow as well improving climate within a building.

It uses galvanised steel within its construction which enhances strength and helps to deliver safety for personnel and equipment. Overall it is tested and certified for full compliance and is UKAC/CE approved for full standard conformity.

As more and more Atlantic storms are forecast to hit the British Isles there has been increasing demand for Hart’s Speedor Storm doors. Speedor is Hart’s trusted, innovative, solution for the ‘high-speed’ door and it has been developed further for specific manufacturing requirements, hence Cleanroom, Conveyor, Mini and of course Storm. All feature cutting-edge technology and a commitment to excellence in applications where operational efficiency, safety and reliability are required.

The Speedor Storm variant offers protection from the elements, withstanding winds of up to 70 mph. The wind resistance is delivered via a unique guide system working in combination with other carefully designed features. Strength is through multi-layered PVC and textile which are both long-lasting and tear-resistant. Horizontal curtain braces add additional wind resistance. Seals are also a key feature provided by PVC extrusion and rubber draught seals. Safety features are paramount and the Speedor Storm includes a pressure-sensitive bottom edge, anti-fall protection and photocell technology.

Operating methods include floor loops, radar, photo beam, radio, movement sensors, hand-held or vehicle-mounted radio transmitters, push button and pull cords. Operation can be set to include or exclude pedestrians as desired. Warning lights or klaxons can be incorporated and the operation of a Speedor Storm can be integrated into a Building Management system if required.

Hart’s Speedor range can meet a wide range of requirements. As an example and moving away from the rigours of climate, four Speedor high-speed doors have been installed by Hart Door Systems at a major frozen and cooked meat manufacturing facility. The doors are just 1.5m wide and 1.95m high, the second smallest Speedors ever manufactured by Hart.

The contract demonstrates that the Speedor range is available not only in distinctly different types of doors but, where applicable, the doors can be available in reduced sizes for precise requirements.

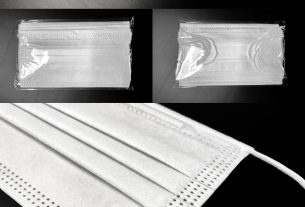

In a recent contract there was a need to protect the production environment against drafts, humidity, dust and dirt. This was achieved by installing Speedor Cleanroom with its fast opening and closing speed. The pharmaceutically standard Speedor Cleanroom controls airflow thus reducing contaminants.

Designed specifically for manufacturing and research facilities, Speedor Cleanroom works in environments where hygiene standards are high such as pharmaceuticals, electronics and micro-mechanics industries.

The main features of Speedor Cleanroom include maintaining strict air leakage requirements over specified pressure differentials. Complete with an intelligent control panel with digital display each Cleanroom has a reliable and clean in-line drive system complete with an integral safety brake and a non-touch safety light curtain to protect personnel.