Designing vibration isolation systems to ensure sensitive scientific and medical equipment operate effectively usually involves working to a specification with very demanding vibration criteria. Conventional isolators such as spring mounts are often unable to deliver the required level of vibration control. Here, Adam Fox, engineer and director of vibration engineering specialist Mason UK, explains how and why air springs are often the optimal isolator in these scenarios.

In facilities such as electron microscopy suites or semiconductor plants, even the lowest levels of vibration can have a significant impact on equipment performance. Disturbances created by road traffic, nearby rail lines or even people walking around the building can interfere with measurements or imaging. Vibrations imperceptible to human senses can be problematic.

Air springs offer the best isolation of all isolator types, so are the ideal solution for these applications. However, they are also required in any scenario where the isolator needs to provide a higher level of performance than you can expect from springs or rubber. A good example would be a generator placed on a thin structural slab.

Meeting stringent specifications

In highly sensitive environments, vibration criteria well below the threshold perceptible to humans, such as VC-E or VC-F, are often specified. These set limits that ensure the equipment will operate correctly, but are extremely difficult to achieve in challenging locations such as near railway lines or in busy buildings, without specialist engineering.

Traditional spring mounts are widely used across mechanical and electrical plant rooms and are highly effective in isolating HVAC systems or general machinery. However, when the requirements become exceptionally stringent, their limitations become apparent.

Steel springs are, by their nature, stressed metal wires. This means they have inherent vibration modes that can be excited by certain frequencies, which can breach low vibration power thresholds. As engineers must make springs softer to achieve lower frequency isolation, the stability of the system can also become an issue, with small changes in loading capable of causing unwanted movement.

Adding damping can help address the stability issues, but often at the expense of isolation performance, making it hard to achieve the very low vibration levels required by advanced scientific and medical equipment.

Understanding air springs

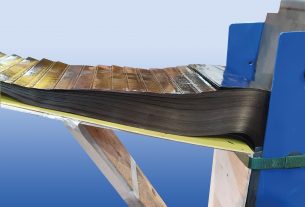

An air spring isolator operates on a different principle. The equipment is supported on a pressurised rubber bellows, which can be filled with gas such as nitrogen and adjusted to maintain level under changing loads. Essentially, the equipment is supported on columns of air.

Crucially, this avoids many of the resonant responses seen in conventional spring isolators and provides isolation against low driving frequencies that conventional isolators cannot. Air spring systems automatically level by adjusting the pressure at each support, should there be a weight shift. The result is a stable platform that can meet or even exceed the most demanding vibration specifications. Air springs can provide extremely low natural frequencies, often below 2 Hz, while remaining stable.

These qualities make air spring isolators the solution of choice for environments where precision is paramount. They are commonly used beneath electron microscopes, MRI scanners and other high‑precision imaging or metrology systems. However, they should also be considered for more conventional projects such as isolating transformers or generators, which can easily excite traditional elastomeric and spring isolators.

Air springs in action

A good example of the effectiveness of air springs is the Cardiff Innovation Campus, where Mason UK designed and installed a bespoke system to isolate a large electron microscope from vibrations caused by nearby rail traffic. The proximity of the railway line to the facility made this project uniquely challenging. The solution combined a high‑mass inertia base with air springs, resulting in performance that not only met the strict VC‑E criterion but exceeded it, achieving levels close to VC‑G. Such outcomes are exceptional, particularly given the site’s challenging conditions.

Successfully implementing an air spring isolator system requires careful design at every stage. Engineers must accurately calculate loads and ensure they are evenly distributed. The surrounding structure, including pit depths and architectural constraints, must be considered, and additional factors such as electromagnetic shielding can add further complexity. With the right expertise, however, these challenges can be addressed, enabling state‑of‑the‑art facilities to operate, even in circumstances where freight trains are passing just meters away.

As research and manufacturing technologies continue to evolve, specifications demanding the highest vibration criteria will become more common. Air spring isolators provide a proven route to achieving these demanding performance levels, making them an essential consideration for any project where precision and reliability cannot be left to chance.

To read more about the Cardiff Innovation Campus and other Mason UK projects, visit the case studies section of the website.