At the very forefront of advanced material technology is the aerospace industry – a sector driven by the demands for ever-increasing material strength, durability and optimisation.

A sector pushing the boundaries of innovation, the machining of heat-resistant superalloys (HRSA) and composite materials is an everyday challenge for the industry – and this is where Tungaloy-NTK UK offers solutions beyond the realms of conventional cutting tool manufacturers.

With the amalgamation of the world’s leading ceramic and carbide cutting tool brands, the combined expertise and product portfolio now introduces a wealth of opportunities for manufacturers in this fast-paced marketplace.

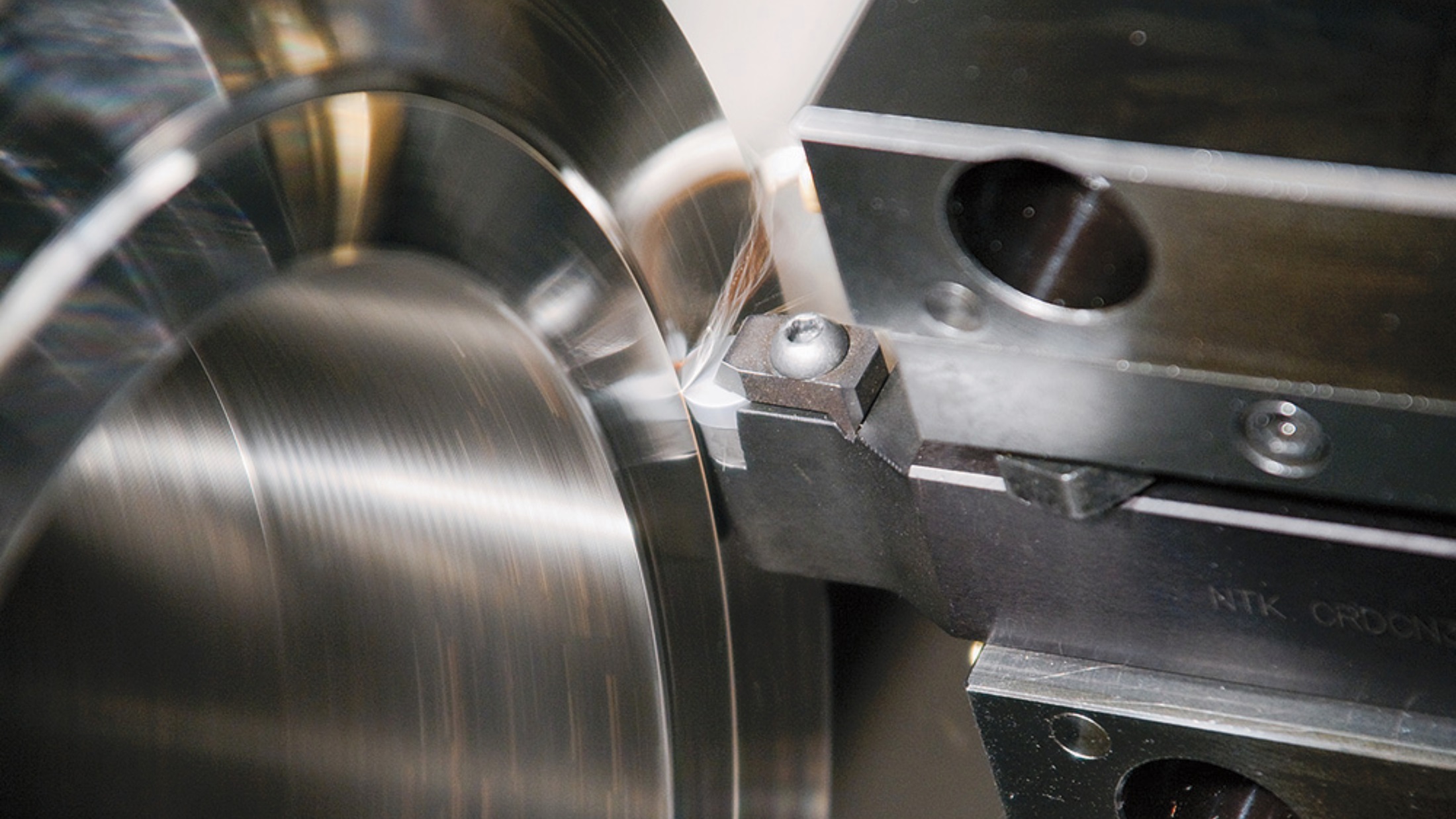

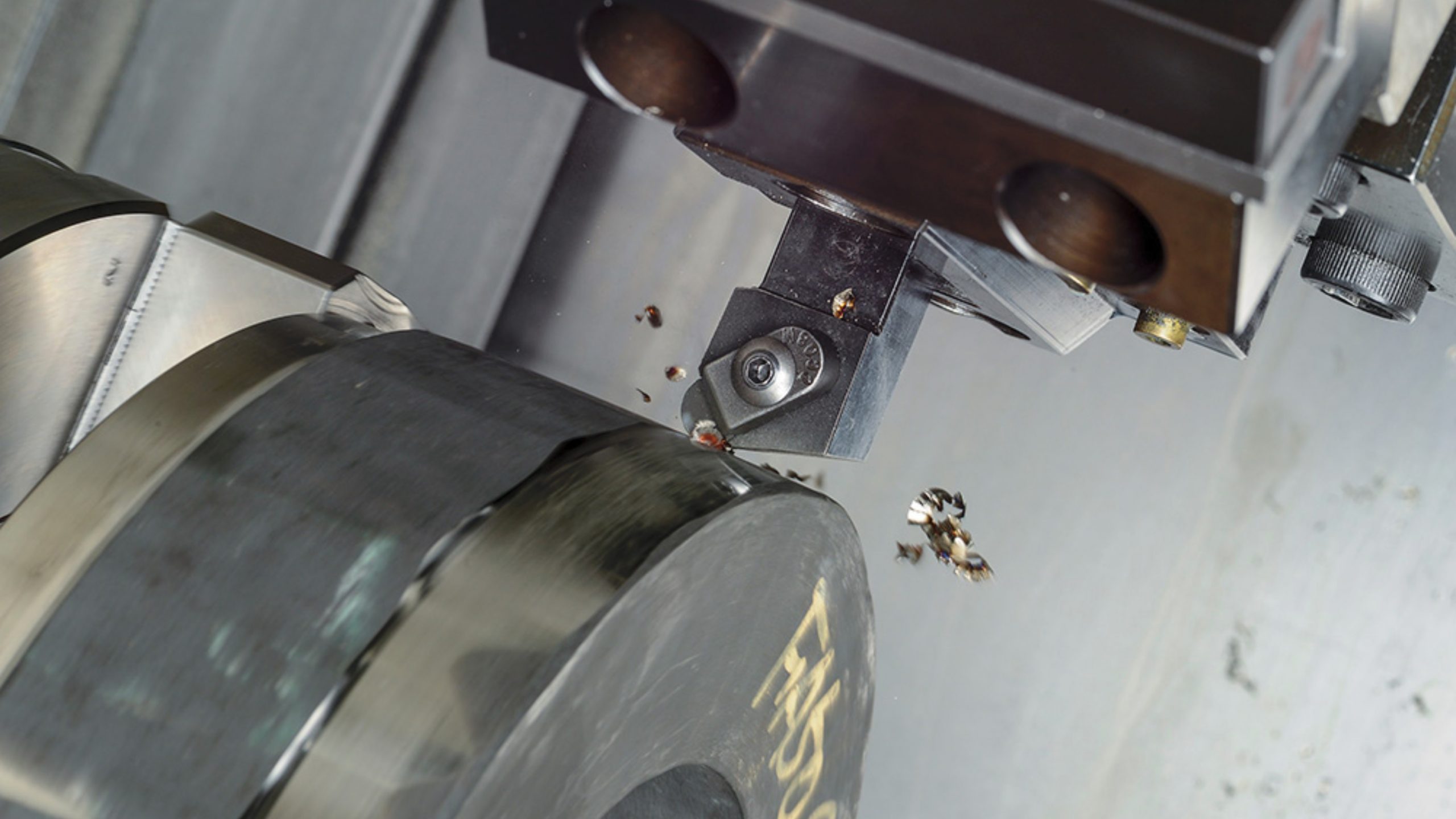

At the very forefront of innovation for increasing productivity and efficiency is the new Bidemics grade of patented inserts. Compared to whisker ceramics which are renowned for high-speed machining, the Bidemic range can more than double cutting speed and significantly extend tool life.

As part of the Bidemic family, Tungaloy-NTK UK is now presenting the innovative JX1 grade that offers cutting speeds close to an incredible 500m/min on aerospace alloys.

Perfect for everything from turning, internal turning, grooving and boring applications, this extremely hard grade provides unparalleled durability with cutting speeds on hard materials that will take your productivity to the next level. Complementing the JX1 grade is the new JX3.

Where the JX1 offers wear resistance that takes tool life to a new level, the JX3 grade has been specifically designed for the toughest of operations. Perfect for rough machining, profiling and semi-finishing, both the JX1 and JX3 can machine at parameters from 180 to 480m/min with a depth of cut up to 2.5mm and a feed rate up to 0.27mm/rev.

Complementing the JX1 and JX3 series is the JP2 grade for high-performance finish turning. Capable of achieving cutting speeds 10 times higher than carbide equivalents, the JP2 achieves unparalleled productivity levels.

With machining in the realms of 520m/min possible, the JP2 delivers superior surface finishes of Ra0.6µm with a feed rate of 0.15mm/rev. The JP2 features multi-edges and a TiN coating to maximise durability and efficiency.

Providing added flexibility for high-performance turning, Tungaloy-NTK UK has also introduced its new BX815 CBN grade for high-speed finishing. Extending the application range of the patented JX and JP Bidemic grades, the BX815 is perfect for both external and internal finish turning in the speed range from 80 to 500m/min – making it the allrounder for manufacturers that demand exceptional surface finishes on heat resistant alloys.

Designed for machining superalloys, the BX815 incorporates Alumina-based binders and Zirconia grains that offer heat dissipation, oxidation and fracture resistance.

Complementing this are the fine CBN particles that contribute to outstanding surface finishes to improve the quality and aesthetics of your machined parts.

Unlike the ceramic grades of the past where capability and flexibility were compromised for performance, the SX Series changes that perception.

Specifically formulated to handle the intense demands of rough to semi-finish machining, the SX series offers a balanced combination of toughness and wear resistance, making them suitable for applications from machining turbine casings to blade machining.

The exciting SX3 Sialon ceramic grade is perfect for rough and semi-finish high-speed turning and milling of heat-resistant alloys. Hitting its sweet spot on materials like Inconel 718 and Rene, the SX3 is your go-to solution for high-performance machining of heat-resistant alloys.

Also developed for rough to semi-finishing of heat-resistant alloys, the SX7 Sialon ceramics grade provides improved boundary wear resistance to prevent cutting-edge wear and breakage, prolonging tool life and consistency.

With excellent thermal shock and better flank wear resistance than other Sialon grades, the SX7 is the choice grade for semi-finishing turning, grooving and milling of materials like Inconel and Waspaloy. The SX7 is complemented by the SX9 – perfect for roughing operations in milling and turning.

The new AH8000 series for machining HRSA materials is the perfect all-rounder with insert geometries and grades for turning, grooving, threading and milling. The AH8000 incorporates the AH8005 and AH8015 grades that have an advanced nano multi-layered AlTiN coating to enhance wear and heat resistance.

The AH8015 is a versatile grade that provides an excellent balance between wear resistance and fracture resistance, making it the first choice for machining challenging materials under general cutting conditions. In contrast, the AH8005 is the perfect grade for finish machining.

The UK team are regularly encountering customers that are achieving surface finishes in the realms of Ra0.6µm when machining Inconel 718 at speeds over 150m/min at feed rates of 0.15mm/rev.

If you want to discover how the Tungaloy NTK UK team can revolutionise your machining operations, reduce your cycle times and costs, email: salesinfo@tungaloyuk.co.uk or visit: www.tungaloy.com/uk / www.ntkcuttingtools.com/uk/