In response to increasing pressure from high utility costs, West Midlands recycling specialist QC Polymer has entered administration.

Hasib Howlader and Nimish Patel, licensed in the UK by the Institute of Chartered Accountants England and Wales, have been appointed as joint administrators of the company and will run the business until suitable buyers can be found for all assets.

QC Polymer, a PET recycling company based in the West Midlands, UK, entered administration on 29 October 2024 despite ambitious expansion efforts after its acquisition by India-based Mysore Petro Chemicals in 2024. Under new ownership, the company had aimed to achieve revenues of £100 million within five years, leveraging innovations in recycled polyethylene terephthalate (rPET) technology.

Hudson Weir now invites serious interest from potential buyers looking to acquire the full suite of specialised, high-tech machinery used in QC Polymer operations.

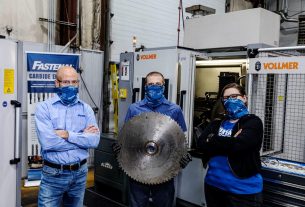

Hasib Howlader [pictured], Director at Hudson Weir said: “It is sad to see a green technology business at the forefront of its sector failing due to increased utility costs, in the case of QC Polymer. Brought about by the rising cost of fuel, perhaps it’s time for governments to look at the sustainable environmental businesses in the UK, and help them to thrive. Where the public are incentivised to reduce carbon footprint, I believe that the Government should provide similar incentives to businesses in the environmental sector such as QC Polymer through reduced energy rates.”

Hudson Weir has appointed G J Wisdom & Co as valuers and auctioneers to oversee the sale of QC Polymer’s state-of-the-art plastic bottle recycling plant. Located in the West Midlands, this modern facility is dedicated to post-consumer bottle reprocessing, featuring a comprehensive production line including:

- Bail Break, Trommel Separator, Cap & Label Separator, Tomra Autosort Bottle Sorter with EM3 Metal Sensor

- Ken Mills Aries Horizontal Bailer, Label Remover, Pre-Washer, Granulators, Floating Tanks, Centrifugal Dryers

- Steam Boiler, Hot Wash Tanks, Hot Air Drying System, Blow Down Vessel, Tomra Optical Flake Sorter, Eddy Current Separator

- Discharge Silo & Twin Bagging Stand, as well as various connecting conveyors

Supporting equipment includes a Boge Direct Air UK Air Compressor with a 1000L Tank & Dryer, two Polymer Preparation Systems, a Dissolved Air Floatation System for water filtration, a weighbridge, and other associated assets. This production line currently outputs 18,000 tonnes of 100% clear rPET flakes per year, utilising top-of-the-line TOMRA Innosort flake sorters and NIR-equipped auto-sort bottle sorters to ensure the highest quality standards.

With an original setup cost of £1.2 million in 2021/2022, this advanced plastic bottle recycling plant, expected to attract significant attention, is now available by sealed bid tender. The deadline for submissions is 2pm on 11th November 2024.

Open viewing will take place on 6th November 2024, at Unit 14, Cannon Business Park, Gough Road, Bilston, WV14 8XR. The successful bidder will be informed promptly following the tender deadline.

Interested parties should submit completed tender forms directly to the auctioneer or their authorised representative by the specified deadline. For expressions of interest, please contact Garry Wisdom of G J Wisdom at garry.gjwisdom@gmail.com.