Outsourcing processes can be counterproductive, especially when components arrive late or are poor quality. Birmingham-based Edmar Engineering Company Ltd has taken control of its cutting capabilities, splashing out on a A-1212 waterjet from WARDJET – and the business benefits have proved manifold.

Fourth generation family-run business Edmar Engineering celebrates its 80th birthday next year, but its service provision is cutting-edge as ever, thanks to its latest acquisition – a WARDJET A-1212 waterjet machine.

Edmar was founded in 1945 by former Dunlop foreman, Bill Marklew, and partner Mr Edwards. Having been commandeered by the MoD to enlist skilled, local engineers and toolmakers in the war effort, Bill decided to retain his new-found colleagues after the war and set up his own specialised precision engineering company.

Here and now!

Nearly eight decades on and with Bill’s great granddaughters, Anna Hayton and Jayne Sheppard, at the helm alongside Technical Director, Richard Dale, Edmar is still true to its roots.

The company specialises in small quantity machining, prototypes, one-offs, jigs, fixtures, and special purpose machines. From its original manufacturing base in Birmingham, Edmar offers expert support to all sectors including automotive, aerospace, utilities, food, and pharmaceuticals, working closely with customers on time-sensitive projects that require tight turnarounds.

“Our engineers love a challenge and creating things for our clients!” enthuses Co-Director Anna Hayton. “To meet their demands, you have to be reactive,” she asserts. “We don’t carry a huge order book going forward, so much of the work we do is reactive – everybody needs it now!”

Prior to purchasing the A-1212, Edmar outsourced their waterjet cutting requirements, but this solution was becoming increasingly problematic for the company, as Technical Director Richard Dale explains:

“When you subcontract, you lose control over quality and lead times,” he says.

“If you’re relying on parts coming in that have been produced elsewhere, they can arrive late and with a different finish than you wanted. Those parts may then need reworking, which affects everything from timescale to overall quality.”

“By bringing the waterjetting in house, our reactivity and control is much improved. If someone has an urgent requirement, we can manufacture speedily whilst maintaining our high standards. Being able to do that helps us satisfy our existing customer base and has won us new business.”

The waterjet has also helped speed up Edmar’s milling processes by producing profiles prior to milling.

Time-efficient, cost-Effective

The WARDJET A-1212 has not only improved Edmar’s efficiency over the last 12 months; it’s also made the company’s use of materials more cost effective, as Simon’s observed:

“We mainly use the waterjet to cut aluminium, and some plastics, which it can do very fast. Previously, we were buying material cut to order, which can incur extra time and cost; now we can buy a sheet and cut the pieces ourselves.”

“We don’t have to wait for materials to arrive on site any more or wait for them to be cut to size, which has really sped up our processes,” Richard adds.

The right machine

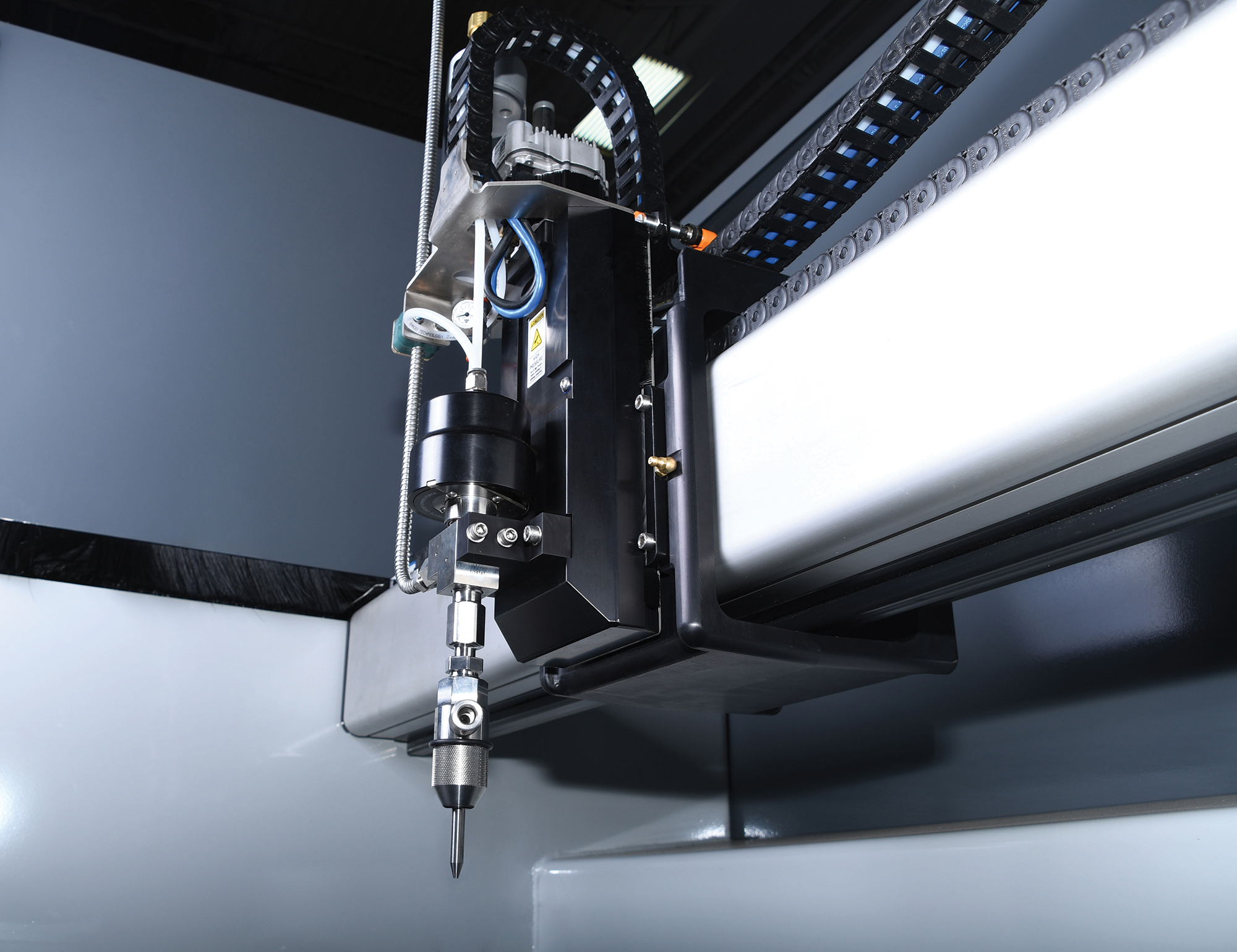

WARDJET’s A-series waterjet is available in two sizes: the A-6012 and A-1212.

“We opted for the A-1212 for its generous 1200 x 1200 operating window,” explains Richard. “It has industrial capabilities with a compact footprint and is ample for the work we do.”

Edmar’s Production Manager and machine operator, Simon Danks, also had a hand in choosing the new machine, which features drag- and-drop loading and part queuing technology:

“It’s a very user-friendly operating system – easy to operate and programme,” he says.

“The dropdown menu of pre- programmed parts is one of the most useful features. If I want a rectangular part, I select ‘rectangle’ from the inventory and the size I want, and the software draws it up for me. It couldn’t be simpler.”

The right partners

After researching the waterjet market, Richard chose Telford-based WARDJET Waterjets from AAG Tailored Cutting Solutions following an impressive hands-on demo experience, where he was able to bring his own CAD files to the WARDJET Demo Room and see the A-1212 go to work on his designs.

“We had a good look at the operating system and were able to programme and operate the demo machine ourselves,” he recalls.

Positive endorsements from fellow industry professionals, and WARDJET’s proximity to Edmar’s headquarters, sealed the deal.

“Although WARDJET machines are manufactured in the US, the UK Telford based-head office is local to us, which means the support and infrastructure is local too.” Richard points out.

“All the training on the new machine was comprehensive and carried out at Edmar. And when we needed extra help with maintenance, WARDJET engineers came out to us to talk us through it. They have a good team of people there. I’m more than happy with the products they’ve supplied and the support we’ve received – I’d recommend WARDJET to anyone.”

Anna adds: “As a small company, the waterjet was a big capital investment for us. We received some grant funding and WARDJET were helpful with the delivery and paperwork requirements of this.