MACH 2020 is just around the corner and Tornos has a real treat for turned parts manufacturers, giving a UK exhibition debut to the MultiSwiss 8X26 and the SwissNano 7. If you’re a turned parts manufacturer looking for something to give you a real competitive edge, you need to see the Tornos MultiSwiss 8X26 at MACH. This machine, one of a family of 3 ranging from 14 to 32mm spindle sizes will appear at the Birmingham NEC from the 20th to 24th April on Stand 538 in Hall 18 alongside, the SwissNano 7 and the TISIS connectivity package that Tornos continually evolves as a seamless Industry 4.0 integration solution.

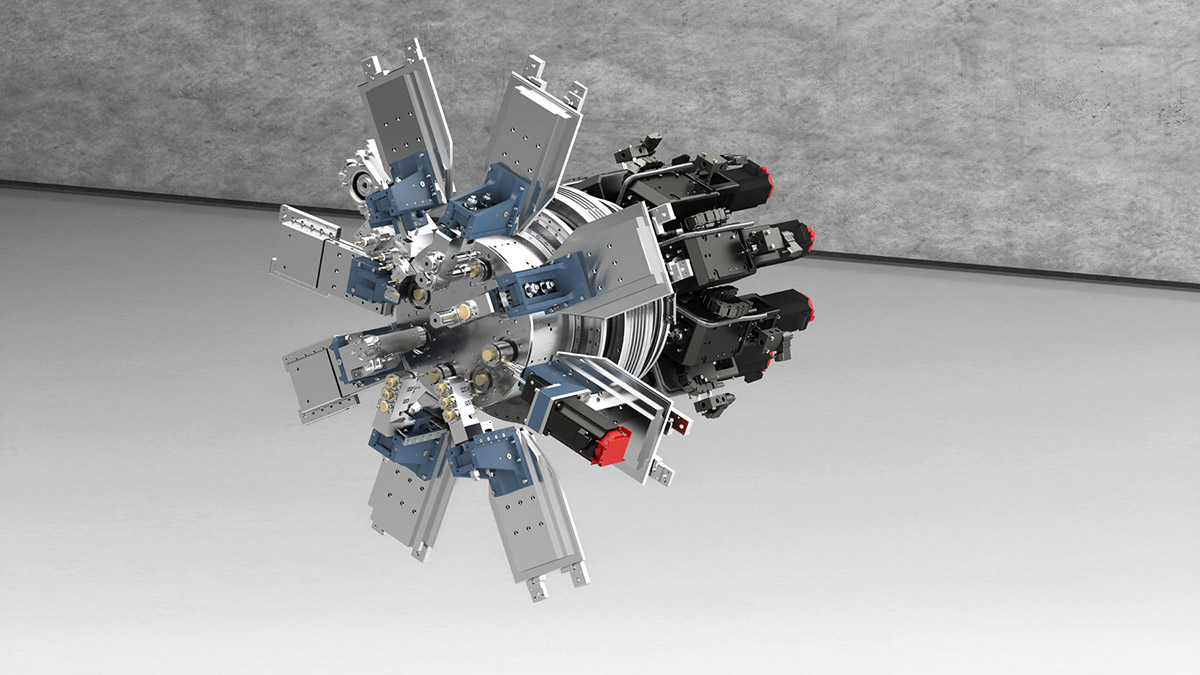

Equipped with eight spindles and eight slides for main operations and accommodating up to three tools per slide, the MultiSwiss 8×26 takes the performance of the MultiSwiss range to a new level, both in terms of component complexity and productivity. With eight highly dynamic synchronous motor-spindles and ultra-fast barrel indexing, the exciting MultiSwiss 8×26 can produce turned parts up to 26mm diameter at staggering productivity levels.

The new MultiSwiss 8X26 incorporates powerful independently operating 11kW motor-spindles that are equipped with a C-axis and counter spindle. Reaching speeds of 8,000rpm in tenths of a second, these advanced motors make a major contribution to performance and productivity. As an option, the machine can be equipped with Y axes to further boost its capabilities. The machine is available in three configurations to meet the demands of the end user and this includes the entry level option of working without a Y-axis; the option with three Y-axes for intermediate applications and the complete machine with six Y-axes for the most complex parts. In each machining position, the operator can tailor the speed and machining conditions as required.

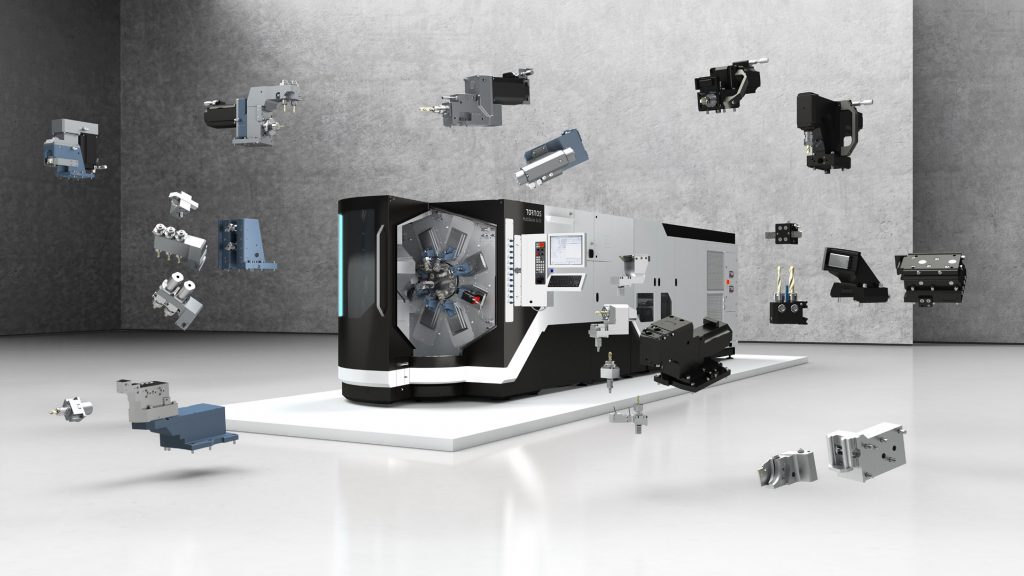

From an ergonomic perspective, MultiSwiss machines are as accessible as single-spindle machines and a single-spindle machine operator can quickly become a MultiSwiss operator. As quick to set up as a single-spindle turning machine, the key difference is that the MultiSwiss is at least five times as productive as a single-spindle turning machine. The machine boasts the largest working area on the market and its exceptional ‘walk in’ accessibility offers real savings when changing over jobs. This concept makes the MultiSwiss as simple to set up as a single spindle turning machine; the only difference ultimately lies in the number of spindle collets to change. Each spindle is equipped with a C-axis and the machine’s hydrostatic spindle bearing technology offers exceptional dampening performance when machining. The MultiSwiss can improve surface finishes and extend toolX life by an average of 30% and up to 70% in some extreme cases, minimising machine stoppages.

The new MultiSwiss also demonstrates seamless integration with all the necessary peripherals built into the machine design. As standard, the MultiSwiss includes the barfeeder, swarf, oil and dual filtration management system – all housed behind the machine in a compact and neat container. Options such as the oil mist extractor, chip conveyor, fire protection system and high-pressure pump can also be seamlessly integrated into the machine.

The highly versatile, pre-adjustable quick-change tool holder system developed for MultiSwiss machines makes full use of the ingenious kinematics that focus upon keeping tools close to the workpiece. As a result, the machine can hold up to three tools in each position, making it incredibly flexible. Tornos offers a range of options to meet user preferences and choices and this includes a FANUC CNC system.

As well as demonstrating the industry’s leading production turning and small part turning technology, Tornos will be giving MACH visitors a demonstration of its Industry 4.0 enabling TISIS process monitoring software. To highlight the ability of the TISIS system to manage and control machine tools remotely, experts will also be on the Floyd Automatic Tooling stand (Stand 472 in Hall 20) with a remote TISIS link to monitor and control the machines appearing on the Tornos stand. Make sure you get a look at the future by visiting the Tornos stand at MACH 2020.