As part of its commitment to the environment, sustainability and social responsibility, Industrial Tooling Corporation (ITC) has now changed all of the packaging on its UK manufactured cutting tools to 100% recyclable materials. The Tamworth headquartered cutting tool manufacturer has always demonstrated best practice in both its manufacturing operation and its environmental impact; making this move to recyclable materials is just the latest step in a continuous drive to reduce the company’s carbon footprint.

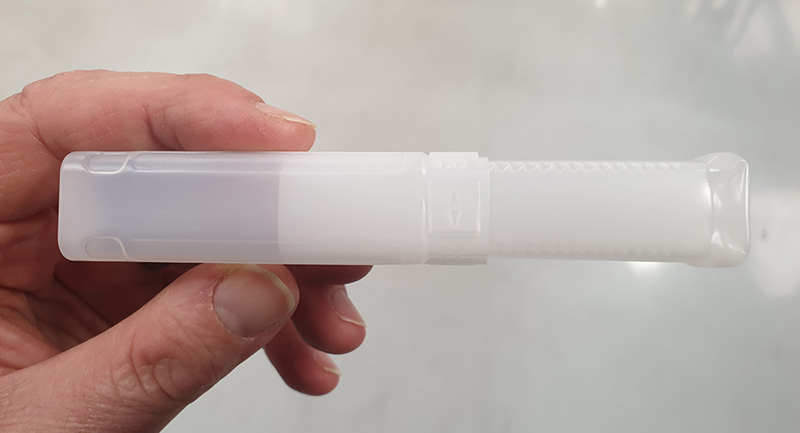

ITC manufactures hundreds of thousands of cutting tools annually using the most technologically advanced and carbon neutral solutions available; and whilst the performance of its cutting tools are reducing spindle load, cycle times and improving machine utilisation to provide cost and environmental benefits to its customers; the issue of plastic recycling and disposal has been problematic to address. That was until ITC’s longstanding packaging partner, Rose Plastic developed its new range of BlockPack and TwistPack Plus Tubes produced from environmentally friendly bioplastic.

Rose Plastic is the UK’s leading manufacturer of packaging for the cutting tool industry and the Rotherham company is delighted to announce that ITC has become the very first UK cutting tool manufacturer to embrace the environmentally friendly packaging.

The new biopolymer plastic is produced using ethanol from sugarcane as opposed to conventional polyethylene, maintaining 97% of the chemical properties of conventional HDPE. This ensures that the packaging retains its performance and appearance characteristics while offering 100% recyclability and sustainability. The new Bio-HDPE packaging has 96% bio-based content that is manufactured from sugar cane. Commenting upon ITC moving to fully recyclable material, Jo Buck from Rose Plastic UK Ltd says: “Rose Plastic is fully committed to its environmental responsibilities and the new Bio-HDPE packaging we are manufacturing has environmental benefits throughout the supply chain. This includes a 14% reduction on materials used in the BlockPack range, huge absorption of CO2 throughout the production process and even the Sugar Cane Bagasse residue from production is recycled to replace conventional energy sources.”

“This is our most environmentally friendly packaging yet, and we are delighted to now have a completely new range of sustainable Bio-HDPE packaging solutions available for 2020. We have a longstanding relationship with ITC; and with both parties being conscious of our environmental responsibilities, this packaging is a huge move forward. ITC is an industry leader in its sector and being the first adopter of this new Bio-HDPE packaging, highlights how the company strives to innovate in all aspects of its business.”

ITC’s Marketing Manager, Georgia Graves comments: “As a business, we have long been committed to reducing our carbon footprint. In recent years, ITC has instigated a range of measures to significantly reduce our oil and fluid consumption, we have introduced new machine tools and technologies that have reduced our power consumption drastically and our recycling programme is extremely comprehensive.

We are committed to our social and environmental responsibilities and having a long-term supplier like Rose Plastic develop this new packaging is another step forward in our journey to becoming carbon neutral.” “Whilst this new Bio-HDPE packaging reduces our carbon footprint and improves our environmental credentials, a critically important aspect is the quality of the packaging. We have to be conscious of the ability of any packaging to protect the high-value contents and eliminate the potential for in-transit damage whilst retaining the quality and aesthetics of our packaging and branding. The Bio-HDPE packaging we have adopted from Rose Plastic meets all of our rigorous quality, aesthetics and performance needs whilst further enhancing our environmental objectives,” concludes Georgia Graves