As a general rule-of-thumb, if the weight of PCD cutting tools is reduced, then significantly higher cutting data can be achieved. To realise the benefits of lightweight cutting tools, MAPAL is now utilising additive manufacturing processes – a process that is also providing complete design freedom for ever more innovative solutions. As 3D printed cutting tool structures can be designed and manufactured to minimise weight without compromising strength or integrity, MAPAL engineers are increasingly pushing the boundaries of cutting tool design and development.

New lightweight bell tool with long tool life

An example of how MAPAL uses the advantages of 3D printing can be realised in the company’s new bell tools with brazed PCD inserts. Bell tools are frequently used in the hydraulic and automotive sectors, with examples being the external machining of hose connections on turbochargers where complex contour requirements must be met with precision. This means that cutting tool production must be equally precise to ensure customers can achieve their cost-effective, precision machining requirements.

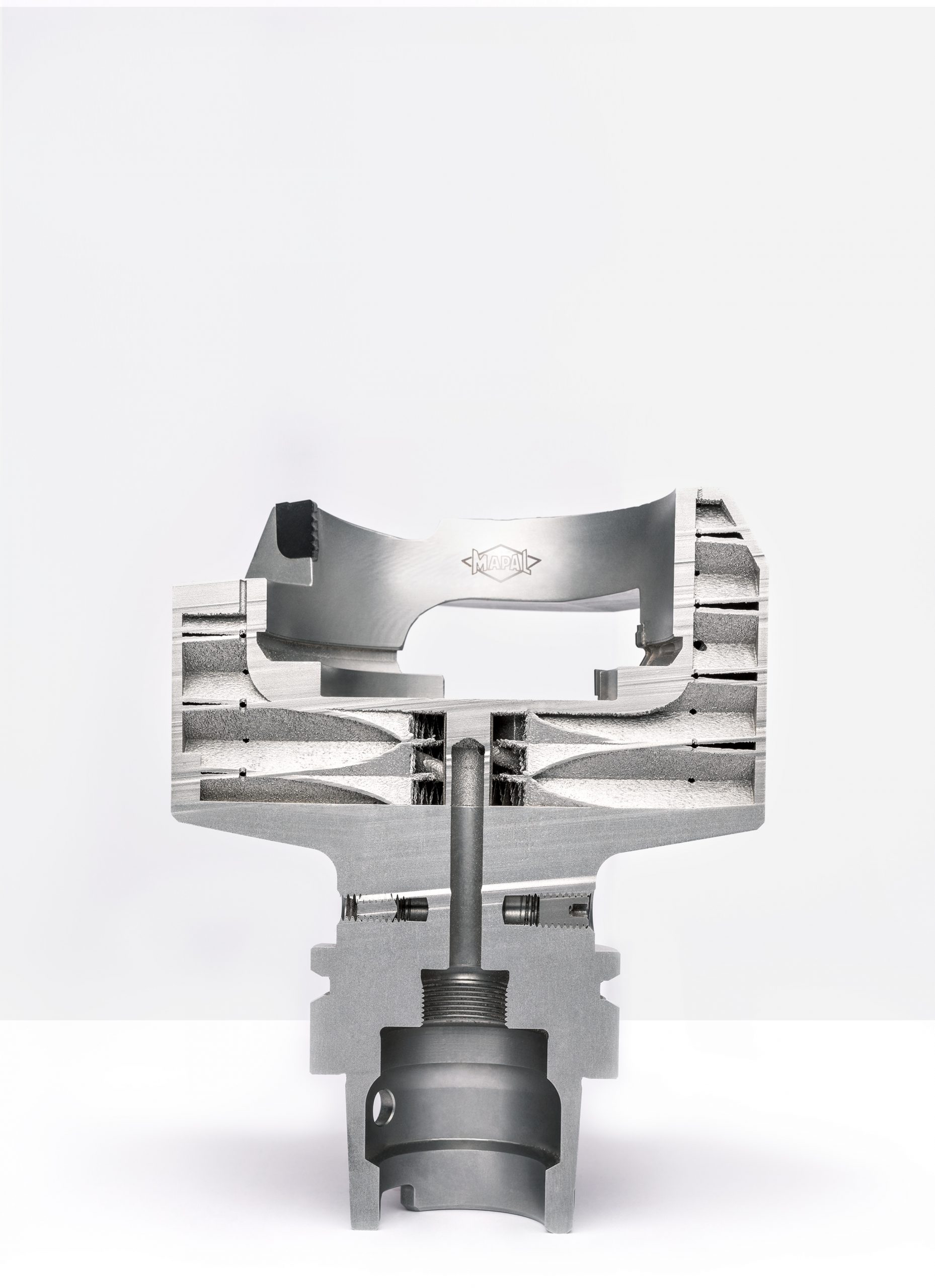

To meet the needs of the end-users, MAPAL has optimised the existing, conventionally manufactured bell tool by integrating selective laser melting process into its manufacturing processes. This allows the inside of the cutting tool to be modified. So, instead of utilising tools with a heavy solid material design, the new MAPAL tools have now been specially designed with a honeycomb structure. As a consequence, the tool is at least 30% lighter and the tool life is increased by upwards of 40%, credit to the enhanced vibration damping characteristics of additive manufactured tool designs. It is therefore possible to machine at higher speeds and feeds whilst retaining the quality demands that MAPAL end users are accustomed to.

Customers using MAPAL’s additive manufactured tools are witnessing productivity improvements in the region of 50%. Additionally, MAPAL experts are using the 3D printing technology to optimise the cooling channels, ensuring that cutting fluid is delivered to the cutting area via the most efficient possible route. The new bell tool is a hybrid design that can be specified by the end user to meet their exact machining requirements. Using selective laser melting, the new tool geometry is printed on a highly precise tool body with an HSK-63 connection. The additively manufactured tool body is subsequently machined to provide the precise platform for the PCD inserts to be brazed into place and then cut to shape using a laser.