As part of the Bromford Group, Bromford Industries Ltd in Leicester is a Tier 1 manufacturer that specialises in the Industrial Gas Turbines (IGT), power generation and aerospace sectors. As a Tier 1 supplier to the world’s most demanding industry sectors and OEMs, the Bromford Group has to balance the delicacies of continuous improvement, innovation and of course, the scrutiny of year-on-year ‘cost-down’ pressure. That is why the prestigious company has a long-term contract in place with MSC Industrial Supply Co., a leading, national distributor of metalworking and maintenance, repair and operations supplies known for providing high levels of service and engineering expertise.

As part of the long-term consumable supply contract with MSC, the experts in cutting tools focused on a goal to achieve a minimum turnover percentage of year-on-year ‘cost down’ improvements. MSC has an extensive product range that is often a necessity for making significant factory-wide ‘cost down’ gains at OEM and Tier 1 businesses as they consolidate their extensive and poor service supply chain. With its access to thousands of brands and hundreds of thousands of product lines that are all supported by technical experts, MSC has continually driven impressive ‘cost down’ results and productivity improvements for each of the four Bromford Group sites in the UK.

With integrated vending stations, continuity of cutting tool supply is guaranteed; but MSC never rests, its service to its customers goes beyond just supplying a product, MSC is always striving to innovate and improve performance at Bromford. Sometimes, this commitment is pushed beyond the bounds of convention with the Bromford Group competing on the global stage for new projects, as global aerospace primes push capacity and innovation from one continent to another.

One recent aerospace engine component arrived in Bromford’s Leicester facility from another Bromford Group facility in Connecticut in the US. Bromford Industries Leicester and its staff had to demonstrate the competence to manufacture the part at speed whilst adhering to the stringent quality requirements – all with very little cutting data. The Leicester site specialises in the production of aero engine, landing gear and marine IGT components for bluechip clients such as Rolls-Royce, Pattonair, ITP, GE, Siemens and Messier Bugatti Dowty to name a few.

MSC Steps up to the Challenge

To manufacture the initial batch of four Inconel 718 aerospace engine components for one of these prestigious customers, MSC applied its technical expertise, drawing from the industries largest team of application engineers, to ensure the complex components could be manufactured to specifications, and on time. With cutting tool datasheets from the US being obsolete due to the tools being unavailable, the MSC experts started from scratch and identified a rationalised tooling portfolio from a variety of suppliers, mitigating any special tooling to undertake the three operations and meet the specified deadlines. Machining the four components on a Doosan Puma 12L turning centre, the MSC solution succeeded in meeting the Bromford deadline for the initial tests.

Continuous Improvement Strategy

With the initial batch complete and the competency to machine the parts proven, MSC Application Engineer Rob Smith knew better results could be achieved. With the second batch of eight parts pending, the MSC technical expert re-visited the engine components, the cutting tools and respective machining strategies. The recommendation was a switch to ceramic cutting tools for the rough turning and grooving operations.

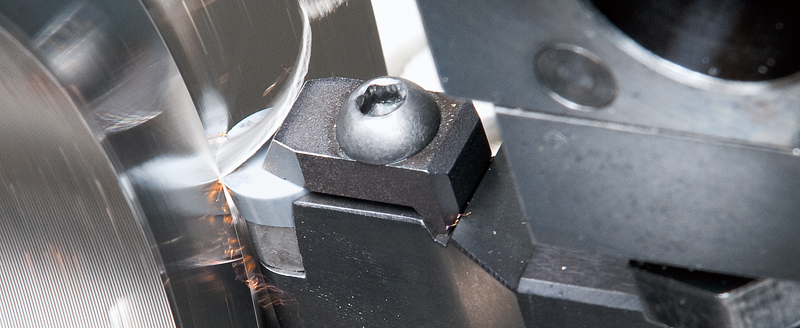

Commenting upon the thought process, Rob says: “At the start of 2020, MSC formed a relationship with world-leading Japanese ceramic tooling brand NTK, and we knew the different physical properties of ceramic tooling would yield impressive results on heat resistant aerospace grade alloys. By nature, ceramic tooling is more brittle and susceptible to breakages if not managed with the correct machining strategy – but on the other hand, it can machine at speeds and feeds 10 to 15 times higher than carbide tooling. We collaborated with Simon Huxtable from NTK and the proposed strategy was to first remove the CNMG and SNMG carbide inserts and replace them with a round RNGN insert from NTK’s SX9 portfolio. The SiAlON grade that combines silicon nitride ceramic and alumina ceramic is claimed to be perfect for machining heat-resistant alloys at parameters way beyond carbide, so we put it to the test.”

“We chose to partner with MSC six years ago, and ever since they’ve been an extension to our business. Because continuous improvement is important to us, we are always looking to make our processes better. With MSC, we know their engineers have the knowledge and expertise to help us achieve our goals. Having witnessed on-site trials in which cost-savings are documented and seeing how they utilise their extensive network of suppliers, assures me that MSC will always recommend the most efficient processes and tooling. This project is one of the many ways MSC has worked with us to seek innovative opportunities for improvement; they are a supply partner who wants us to succeed, as much as we do,” says Andrew Moore, Engineering and Product Quality Manager at Bromford Industries Limited

The Results

After increasing the surface speed from 43m/min to 250m/min with a feed rate increase from 18mm/min to 106mm/min, the results soon followed. Rough turning the face and diameter of the 150mm diameter workpiece, the NTK SX9 RNGN insert not only replaced two previous carbide tools and eliminated the respective tool changeover, but it also slashed cycle times from 180 minutes to 27 minutes for the roughing operation. Whilst the previous carbide tooling method delivered a significant improvement on the original parameters from the overseas plant, the application of NTK’s SX9 ceramic inserts made a huge step forward from the method initially instigated by MSC.

As MSC’s Rob Smith continues: “At MSC, we conduct extensive benchmarking analysis and we have calculated that Bromford would require 312 SX9 inserts to complete a run of 312 parts compared to a requirement of 470 CNMG carbide inserts and an additional 78 SNMG inserts. The NTK insert is achieving a tool life at least 2.5 times better than the previous carbide grade whilst accelerating cycle times to levels never before seen at Bromford.”

MSC also re-visited the previous grooving operation that had been instigated with a world-leading carbide tooling brand, and once again implemented improvements with NTK’s SX9 grade. “We looked at the grooving operation as it was contributing to 22 minutes of the overall cycle time for each part. Whilst extended machining times are commonplace on materials like inconel 718, we were confident we could improve. By applying a smaller RCGX09 insert, we profiled the two grooves in a cycle time of 3 minutes 30 seconds, a huge reduction from the previous time of 22 minutes. Again, this was achieved by maximising the properties of the NTK SiAlON grade to increase surface speed from 30 to 250m/min, the spindle speed from 64 to 530rpm and the feed rate from 13mm/min to 106mm/min.”

As the MSC National Account Manager for the Bromford Group, Lewis Evans says: “Our engineers have demonstrated both our extensive portfolio of available solutions with the recent inclusion of NTK, but also the technical expertise to integrate relatively new brands into MSC accounts where they will make significant impacts.”

“We have completed the initial batches of 4, then 8 and now 41. On the batch of 41 parts, we have created a significant 5-figure financial saving for Bromford and this has arrived by reducing annual tooling costs by 67%, machining costs by 85% and tool changeover costs by 34%. Whilst these statistics are hugely impressive, one of the most stand-out points is that we have reduced machine hours for this single part by 85% from 1060 hours to just 158 hours. This gives the customer additional machine capacity for undertaking other projects. These significant gains are only on one component and one machine. The opportunities for our engineers to go further at Bromford are vast and as always; we’ll strive to achieve the very best results for our customers,” concludes Lewis.