Thame Workholding was established over 75 years ago and is considered as a leader in providing workholding solutions. Having their own factory in Long Crendon, Buckinghamshire they manufacture an extensive core range of more than 500 workholding products, including soft and hard jaws, t-nuts, height pins, bar pullers and jaw boring fixtures. They have a specialist team of in-house designers and engineers who provide custom designed and manufactured workholding solutions in collaboration with clients looking for bespoke solutions to their workholding challenges.

Thame have their own design team who have industry relevant skills and experience and can draw upon over 40 years of specialist solutions they have provided customers in a diverse cross section of industries ranging from Aerospace to motorsport, Oil and gas and medical, they are able to provide solutions where others may not.

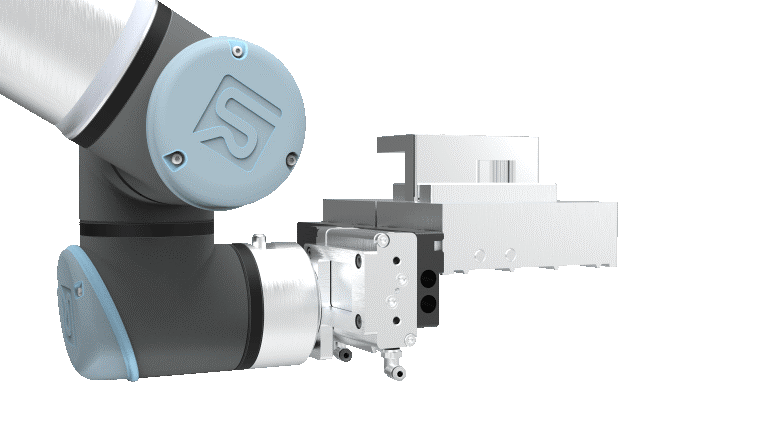

As the UK distributor for many industry renowned workholding suppliers, including Samchully (Chucks and cylinders), Witte (Vacuum and Metrology fixtures), HWR (CNC Zeropoint systems and Specialist chucks) and more recently AirVise, the team at Thame have recently expanded their offering into plug and play robotic automation systems for both Mill and lathe applications.

Sales Director, Marcus Hamlyn explained the decision to front VersaBuilt in the UK.

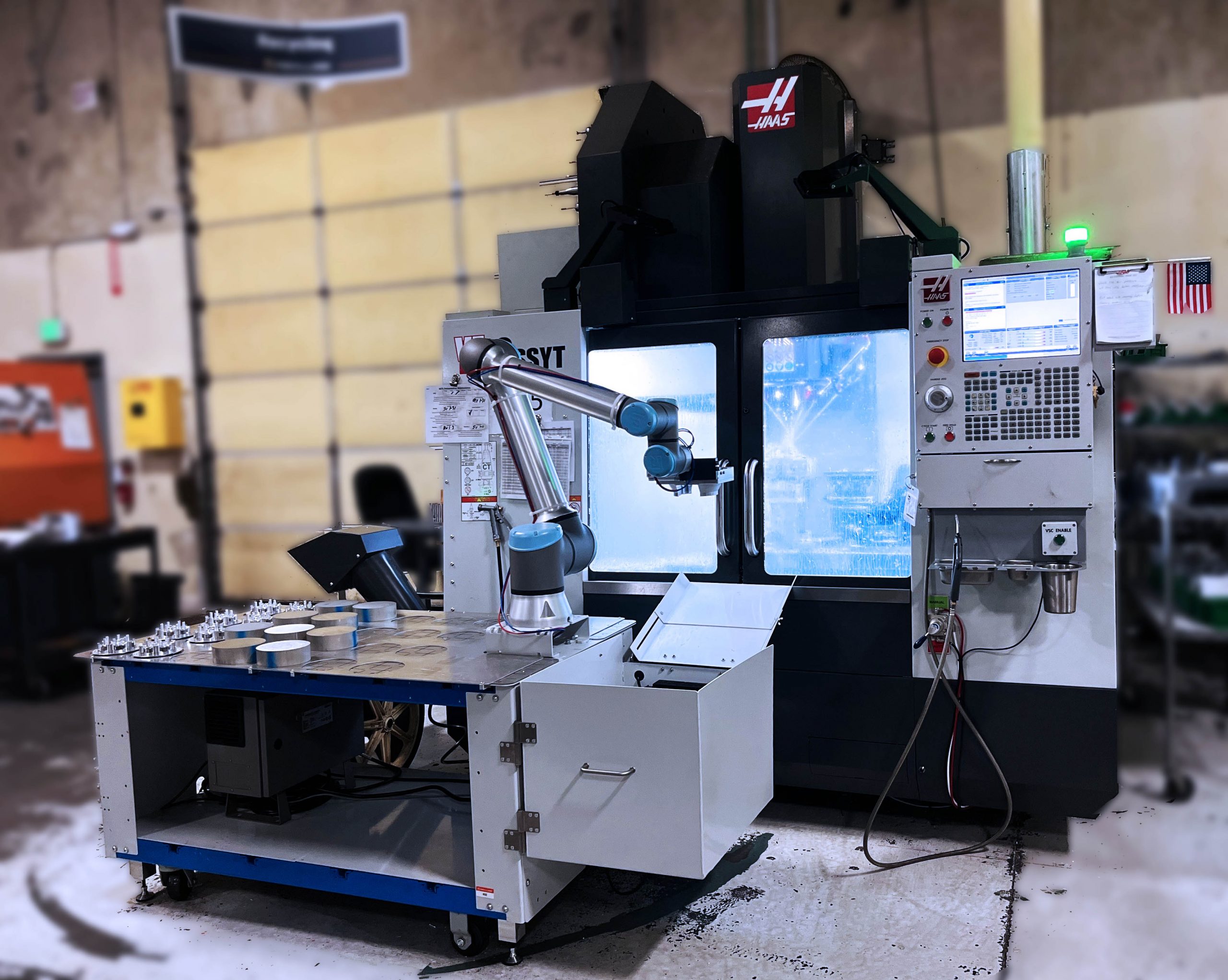

“We feel there is a growing opportunity in the UK market for a simple cost-effective automation solution, and Versa built covers this nicely. The shortage of engineers in the UK is a real problem, there is plenty of work but skilled people are very hard to find so making the best use of your skilled engineers time is vital and this is where automation comes in.”

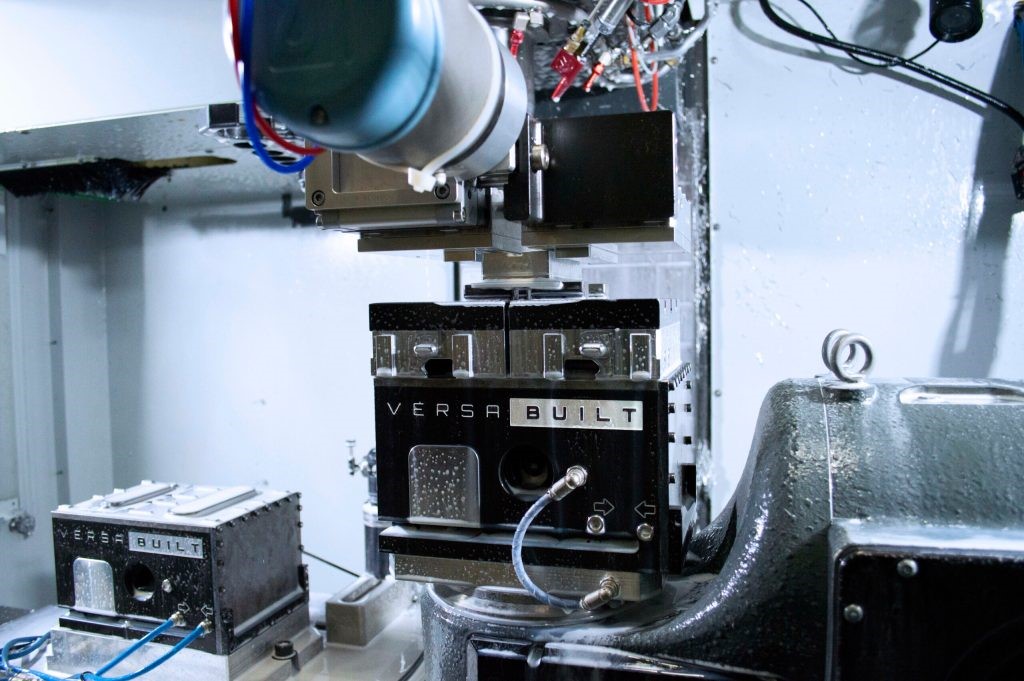

“We look to provide solutions which can assist engineers in improving their productivity, many of which are used within our own factory. More recently we have looked to bring automation and robotic solutions to help engineers to be more competitive and profitable. We already extended our range of workholding earlier in 2023 with AirVise and RAPID and the VersaBuilt system and the additional accessories available will allow a quick ROI for small to medium machine shops looking to grow their capacity out of hours. A typical install including a UR cobot for a Lathe or Mill application is around £55-75K depending on set up requirements, much lower than people may expect!”

“Having offered solutions in the US for over 10 years the team at VersaBuilt seem to have experienced most of the problems end users have in implementing robotic solutions and they have developed not only systems but also software to make the first steps as easy as possible, whilst remaining cost effective.”

“It’s worth noting that this system isn’t just for new machines, many instals are on older machines when the end user needs more capacity and may not be able to buy additional machinery or employ additional staff. The list of machine tools the unit can be integrated with is growing by the day, so don’t assume you we can’t help you out.”

For more details on this system and any other workholding challenges contact Thame Workholding either by phone 01844208050 email sales@thameworkholding.com or visit the website thameworkholding.com