Interface Force was recently approached by an Aircraft manufacturer who wanted to ensure the correct torque and clamping force were being applied to fasteners during assembly.

The Customer’s Challenge

An aeroplane manufacturer needs a solution where they can control the torque when fastening screws on their aeroplane models. They do not want to create any damage to materials or apply too much torque when plane components are being fastened together.

Interface’s Solution

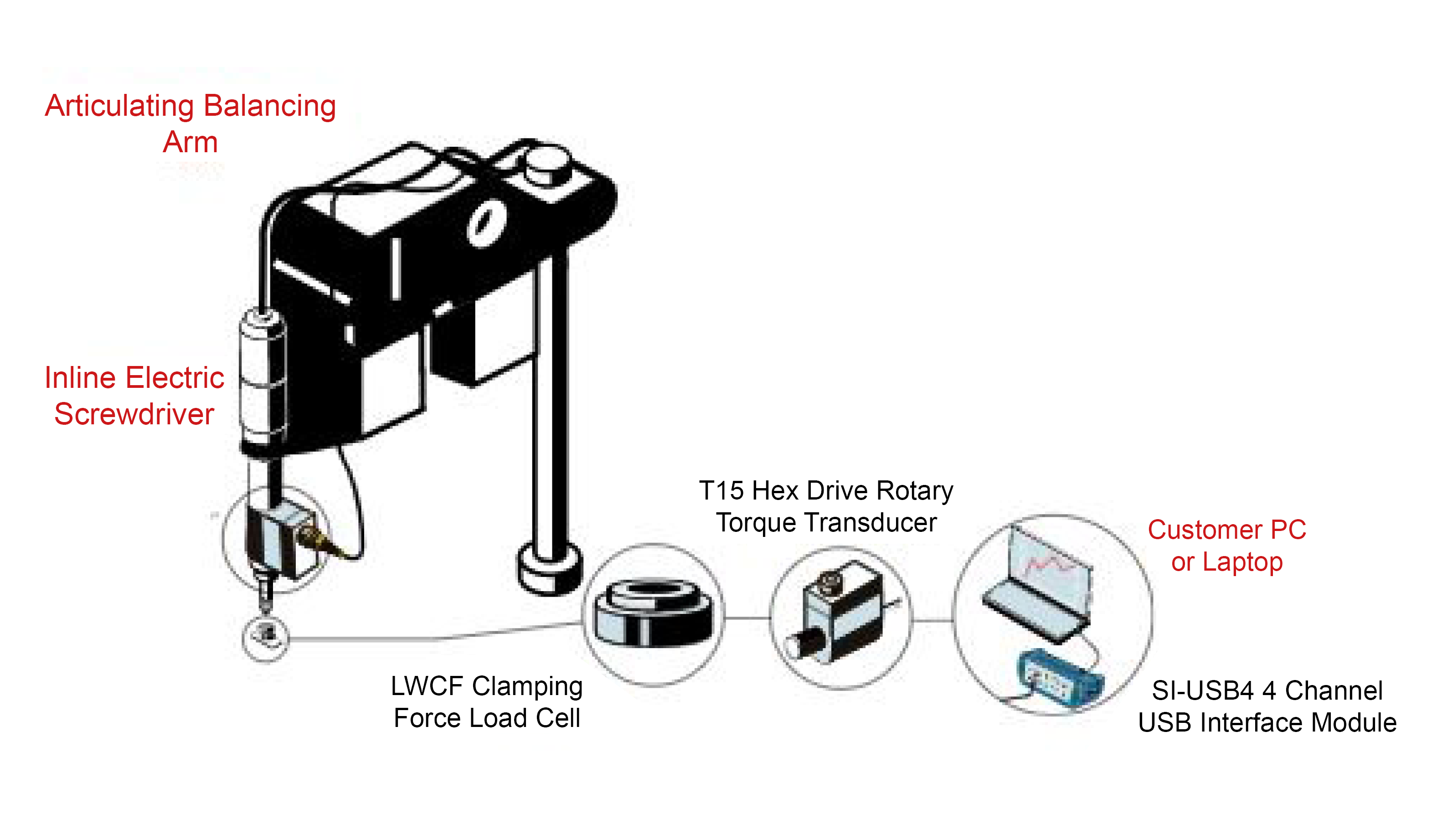

Interface’s Model T15 Hex Drive Rotary Torque Transducer can be attached to the fastening workbench, measuring and recording torque, rotational speed and angle of the screwdriver. The LWCF Clamping Force Load Cell is installed, measuring the forces applied on the screw being fastened. Results are sent to the SI-USB4 4-channel USB Interface Module, which is connected to the customer’s PC or laptop where data is logged, graphed and displayed.

The Results

The aeroplane manufacturer was able to calibrate their screwdriver by measuring its torque, rotational speed, and angle when attaching components to their aeroplane. They were also able to measure the forces being applied to the screw, to ensure it was not applying too much torque to the components.

Items Used to Complete the Test

- T15 Hex Drive Rotary Torque Transducer

- LWCF Clamping Force Load Cell

- SI-USB4 4-channel USB Interface Module

- Customer PC or Laptop

How It Works

- The T15 Hex Drive Rotary Torque Transducer is attached to the screwdriver fastening bench.

- The LWCF Clamping Force Load Cell is placed beneath the bolt head.

- The T15 Hex Drive Rotary Torque Transducer measures the screwdriver’s torque, rotational speed and angle, for the customer to determine the right amount of torque needed to be applied to the screw to prevent any damage to the materials being fastened together.

- The LWCF Clamping Force Load Cell measures the forces applied to the screw, so the customer can determine the maximum torque it can take.

- The measurements and results are sent to the SI-USB4 4-Channel USB Interface Module, where the customer can record the results when connected to their PC or laptop.

For more information about the force and torque sensors mentioned in this application note or how Interface Force Measurements could help with your force, torque or pressure measurement challenges please email us at info@interface.uk.com or visit our website www.interfaceforce.co.uk