Insights from industry leaders like Rolls-Royce reinforced the shared ambition for sustainability across aerospace and beyond.

In October, PCD tooling specialists and the UK’s largest diamond tool manufacturer, Exactaform, joined more than 400 leading manufacturing suppliers and over 9,000 engineering professionals at 2025’s Advanced Engineering event held at the NEC in Birmingham.

Across two action-packed days, the event brought together some of the brightest minds in engineering to network, collaborate, and share real-world solutions to today’s toughest industry challenges. Key players from aerospace, automotive, and defence shared insights and looked ahead to the innovations set to shape the future of engineering in the year to come.

The event gave Exactaform the opportunity to learn from more than 200 expert speakers, connect with peers across the engineering landscape, and gain valuable insight into emerging trends and technologies. Of particular interest were developments within the aerospace sector, where discussions highlighted the increasingly critical role that precision tooling will play in driving performance, efficiency, and sustainability in future manufacturing.

Towards a Sustainable Aerospace Future

Sessions on sustainable aerospace and ESG integration — led by speakers from Rolls-Royce, Innovate UK, and ADS Group — explored how achieving the UK’s 2050 net-zero targets will depend on collective action across the supply chain. From Philipp Visotschnig’s insights on the evolution of sustainable aviation through lightweight materials, advanced aerodynamics, and Sustainable Aviation Fuel (SAF) to Rolls-Royce’s pioneering work on composite fan systems that cut emissions at scale, the message was clear: sustainability and responsible engineering are now central to the future of aerospace.

For Exactaform, these conversations reinforced the company’s ongoing commitment to innovation, efficiency, and environmental responsibility. As industries like aerospace embrace cleaner, more responsible practices, Exactaform continues to play an active role in reducing environmental impact across the manufacturing supply chain.

Exactaform’s Commitment to a Greener Future

For Exactaform, sustainability is a core principle guiding both its engineering and operations. It’s not only about the tools it makes, but how the company designs, manufactures, and collaborates across the supply chain.

Insights from leading aerospace players such as Rolls-Royce, which emphasised the shift towards sustainable design, lightweight materials, and energy efficiency, resonated strongly with Exactaform’s own approach. The company shares this commitment to advancing precision engineering in ways that reduce impact and support long-term environmental goals.

Exactaform’s specialised one-shot tooling solutions are engineered for high-performance machining of complex, lightweight materials. By combining multiple cutting operations into a single tool and delivering exceptional tool life, Exactaform helps manufacturers minimise machine run time, reduce energy consumption, and advance sustainable production goals.

Showcasing Innovation at Advanced Engineering

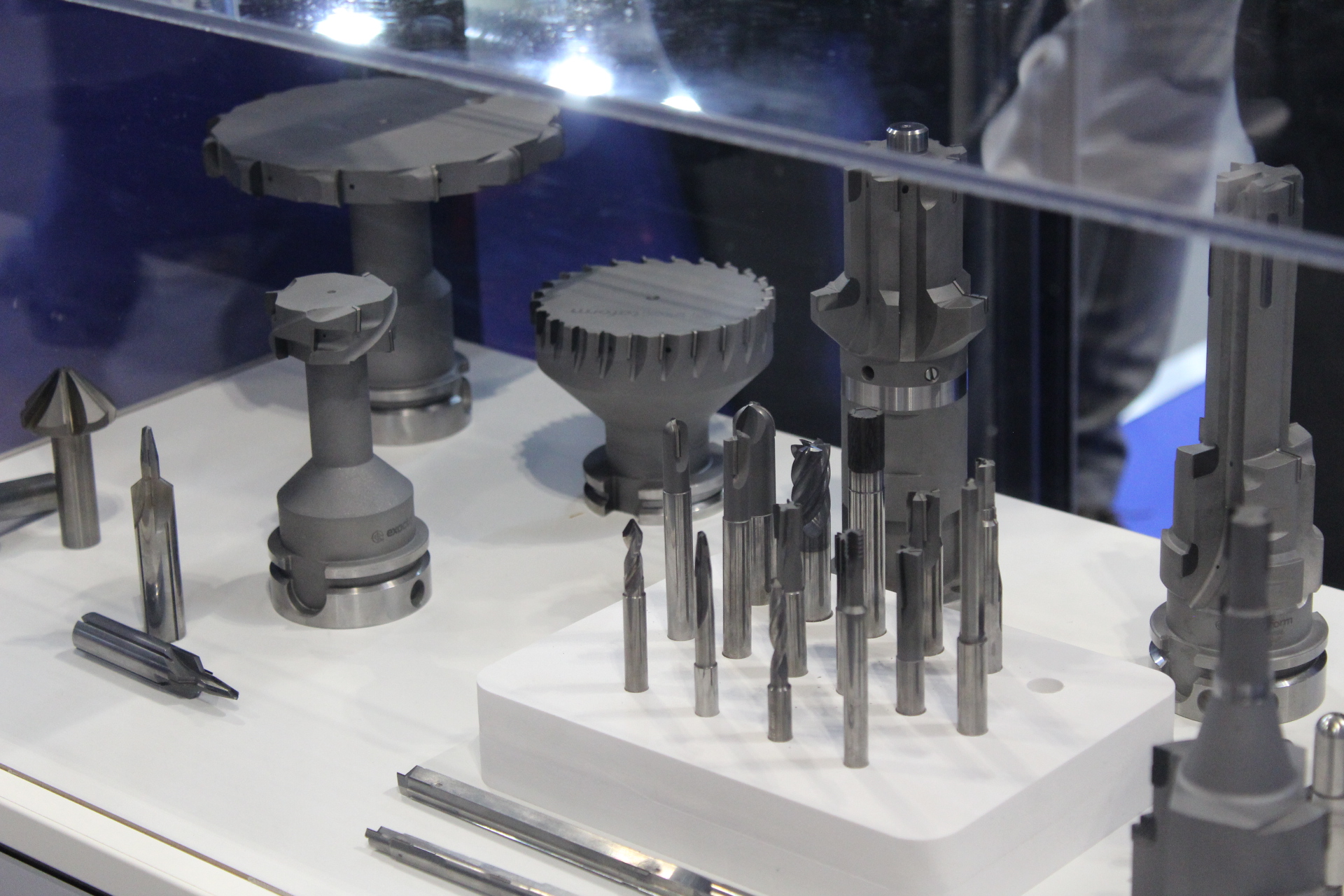

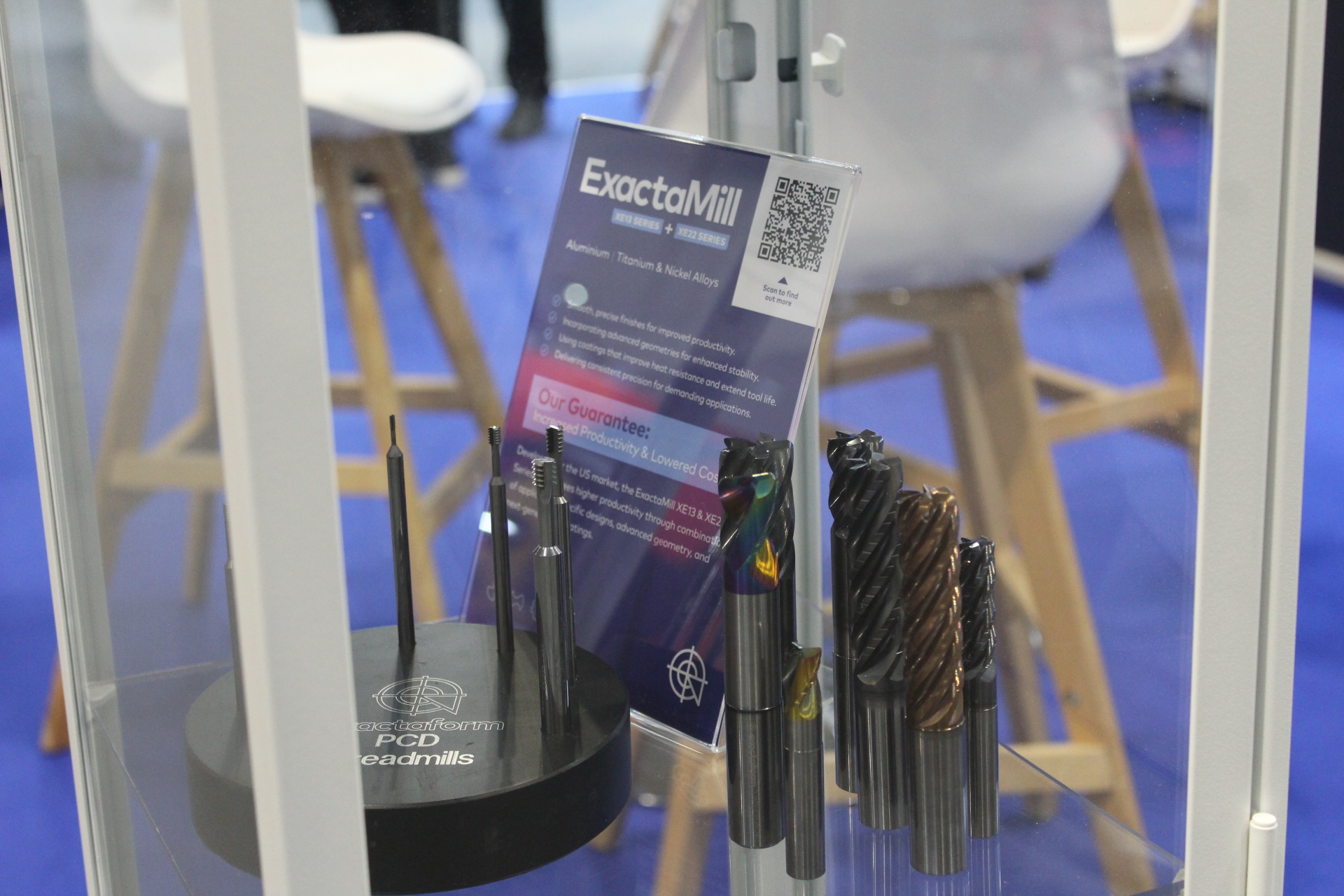

At the event, Exactaform showcased its latest precision tooling innovations for the aerospace and automotive sectors, demonstrating how PCD and carbide tooling can lower cost per part, reduce cycle times, and improve component quality.

Visitors saw tooling engineered for lightweight, high-strength materials such as CFRP, aluminium, and titanium — supporting the industry’s shift towards energy-efficient, low-emission aircraft design. Products on display included the ExactaMil XE13 and XE22 Series of carbide end mills, newly launched in the USA, along with the Exacta-Set milling system — all designed for high accuracy and repeatable performance.

Exactaform also presented bespoke tooling solutions and Recoules countersink cages, underlining its focus on real-world performance — reducing waste, boosting productivity, and helping aerospace manufacturers achieve their sustainability goals through smarter, more efficient tooling.

Reflecting on the event, Exactaform Managing Director Jamie White said: “Advanced Engineering is always a great reminder of the pace of innovation across our industry. It was inspiring to hear insights not only from aerospace leaders, but from manufacturers driving progress across multiple sectors. There’s a clear, shared ambition towards sustainability and a better future.

Hearing from organisations like Rolls-Royce on the next phase of sustainable aerospace reinforced why continuous improvement matters. For Exactaform, sustainability isn’t a side focus – it’s built into how we design, manufacture, and deliver every tool.”