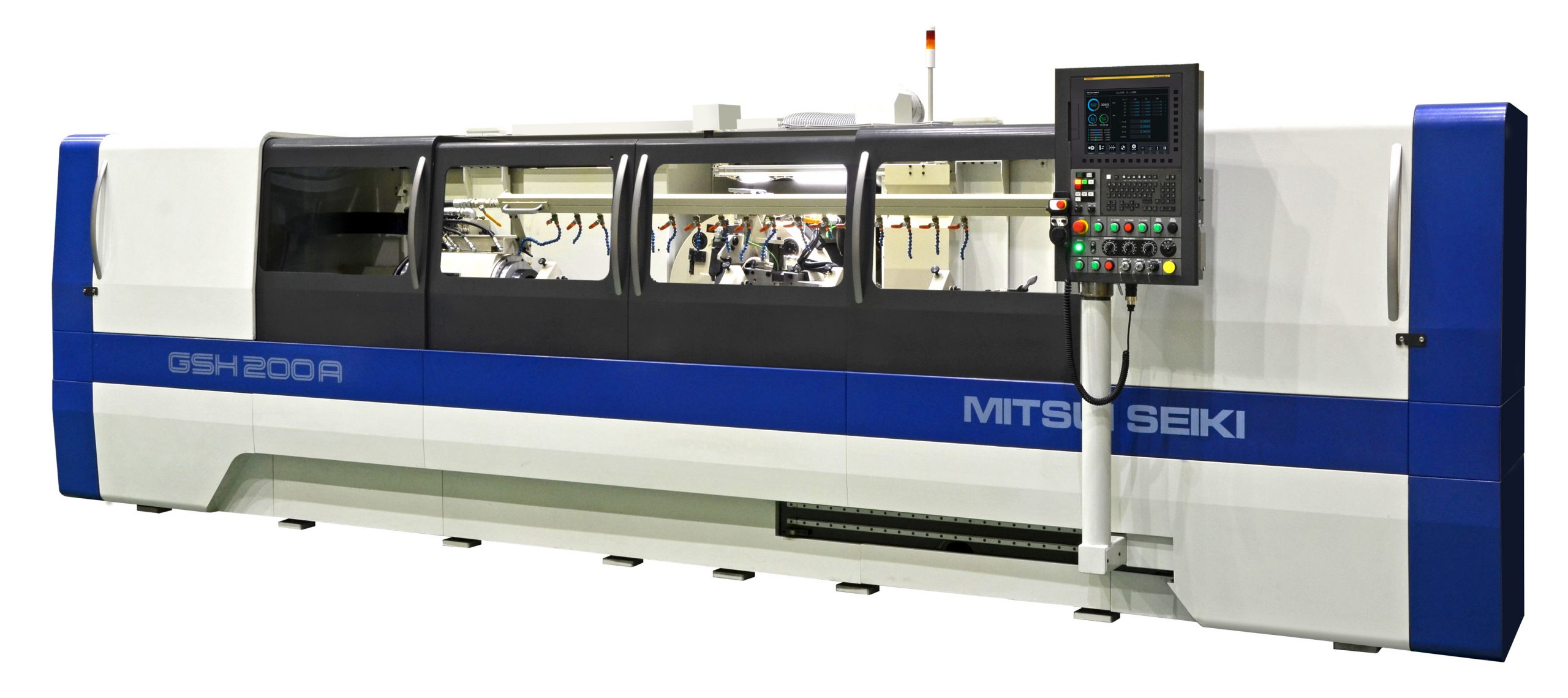

Mitsui Seiki’s GSH 200A Thread Grinding Machine combines flexibility of application, high processing speeds, and consistent precision to complete an extensive selection of threading jobs. The GSH 200A is engineered to handle a wide variety of workpiece sizes. Maximum diameter swing over the machine table is 480mm and distance between centers is 2250mm, enabling the machine to grind a maximum screw length of 2000mm and maximum workpiece diameter of 200mm.

The machine’s capabilities include a 15 kW direct-drive motor that produces maximum wheel spindle speed of 6000 m/min. X-axis stroke of 330mm features a rapid feed rate of 5m/min, Z-axis stroke is 2150mm with 10m/min rapid feed, and maximum work spindle speed is 200 rpm.

Sliding machine surfaces are hand-scraped to maximize precision. In addition, multiple systems minimize thermal displacement that can affect thread accuracy and consistency. Lubricant in the table feed lead screw and shaft core stabilizes temperatures of those components. A main coolant nozzle cools, lubricates, and removes sludge at the grinding point, while separate work area and bed coolant showers equalize internal machine temperatures. Oil and air lubricate and cool grinding wheel axis bearings. The GSH 200A machine is compatible with both oil-based and water-soluble coolant, selectable when the machine is produced.

The GSH 200A permits users to apply CBN as well as standard grinding wheels, facilitating grinding of hardened steels as well as unhardened workpieces. CBN can grind more than 2 times faster than standard wheels while providing longer grinding life, which extends the dressing interval and reduces dressing time per workpiece. Mass production scenarios multiply those benefits. Maximum diameter for standard wheels is 460mm and peripheral speed is 60 m/sec while maximum CBN wheel diameter is 380mm and peripheral speed 120 m/sec.

The machine’s 3-axis NC dresser employs 2 linear axes (U,W) and 1 rotary axis (B) to produce highly accurate profiles in both CBN and standard wheels. A disc-type rotary diamond dresser provides significantly longer dresser life than single point diamond.

Automation features on the GSH 200A include an automatic phase adjuster, automatic notch position adjuster and automatic effective diameter adjuster. Together, the features permit an operator to leave the machine rather than remaining there to adjust the steady rest and oblique diameter during the operation. The auto effective diameter adjuster uses a touch probe to contact the thread groove and measure change in diameter by scanning. An acoustic emissions (AE) sensor built into the wheel spindle provides automatic wheel in-feed position adjustment.

An optional heavy grinding wheel replacement support mechanism facilitates safe and easy grinding wheel and flange changeovers.

The machine’s FANUC 31i-B control features a 375mm touch panel LCD with the newest HMI (Human Machine Interface) technology. Users can move the panel to where it is most convenient to operate.

Mitsui Seiki USA chief operating officer Bill Malanche said, “The GSH 200A combines high performance with flexibility and solid accuracy. It is a highly-productive workhorse thread grinding machine for a wide variety of applications.”