As an engineering solutions company, A&M EDM Ltd is always striving to enhance its operations and capabilities to maximise its service to clients in the aerospace, motorsport, automotive, marine, medical, rail, defence and general subcontract sectors. To achieve this, the West Midlands company has invested in technology from 3, 4 and 5-axis machine tools, EDM wire and spark erosion and laser welding through to temperature-controlled metrology department. When the company wasn’t getting the best out of its machine tools and cutting tools, the company worked with MSC Industrial Supply Co. UK (MSC) to instigate a change of cutting fluid supply, the result was a relationship with the cutting fluid experts at ROCOL.

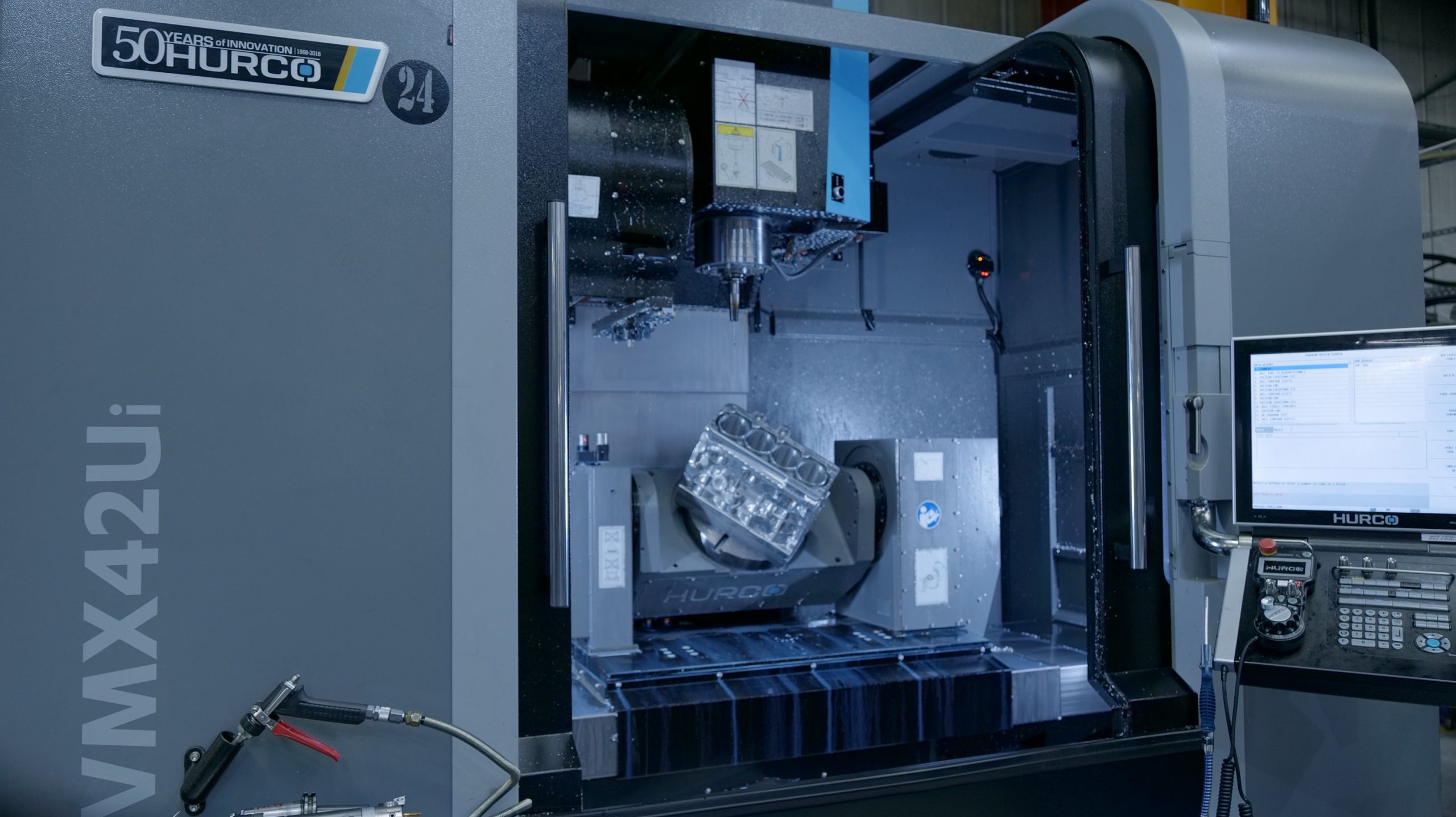

Playing a proud role in the Ventilator Challenge and having more than 57 CNC machines on the shop floor as well as a host of accreditations and accolades, the Smethwick manufacturer utilises MSC to deliver best practice engineering support with frequent onsite visits to proactively identify ways to help A&M EDM to optimise their processes. When it came to improving the performance of its metalworking fluids while maintaining high-quality machining, MSC identified ROCOL as the perfect partner to collaborate with A&M EDM.

Like many subcontract manufacturers, A&M EDM machines a variety of materials that include stainless steel, mild steel, aluminium, inconel, titanium and exotics with a variety of production demands from bespoke one-offs and short runs through to longer run batches for its customers. This variety of materials poses a challenge for any cutting fluid supplier, but ROCOL recommended its ULTRACUT EVO 255 metalworking coolant, an extreme pressure (EP) soluble oil-water mix cutting fluid that replaced the previous coolant. ROCOL and MSC recommended this product as it is not only versatile and suitable for a wide variety of machining applications and materials, but it would also deliver significant saving in the volume of coolant required.

When asked why the company changed cutting fluid suppliers to ROCOL, Gary Surman from A&M EDM says: “We had three fundamental issues. Firstly, we had operators that were complaining about irritated skin. There was also a smell in the workshop. Thirdly, our tool life seemed to be diminishing relatively quickly.”

Asked why the company opted for the MSC route of selecting ROCOL as its cutting fluid supplier, Mr Surman continues: “We are delighted that MSC and ROCOL have come in and analysed our coolant consumption and recommended a solution that will reduce this to half the amount we were using previously. “They invested time in understanding what our objectives were and demonstrated a commitment and determination to help us achieve them. We look forward to an ongoing relationship where MSC and ROCOL will continue to assess and benchmark our machines regularly, helping us to achieve further efficiency and productivity gains.”

ROCOL analysed A&M EDM’s coolant consumption, accounting for the materials and applications while taking samples from active machining operations. The tests at ROCOL’s laboratory delivered a comprehensive report on the current fluid product, with details such as the wear ratio, dilution and consumption. The analysis concluded that coolant usage was much higher than it should be and that A&M EDM needed a versatile, high-performance coolant that would deliver consistent usage and quality results on a range of different materials.

Commenting on the ULTRACUT EVO 255 Mr Surman says: “Once we got the product into the machines, we had no further concerns about skin irritation, the smell had dissipated and we also noticed that our tool life improved. We can only put that down to the EP (extreme pressure) additive that is in the coolant, this gave us that tool life improvement.”

Machine operator Callum Bowen re-iterates the point on odour, stating: “The ROCOL coolant has made a difference. When I get home from work, I no longer smell and the smell does not stick to my clothes, unlike the previous product we were using. The previous fluid created a lingering smell when I returned home from work. This wasn’t very nice to take home.”

“Additionally, the fluid is very good when cutting different types of material. The science behind the coolant is making it much easier for the tools to last a lot longer. Furthermore, the ROCOL coolant does not fog-up the glass screen on the machine doors, so we can see what is going on in the work envelope. This means I can see that the job is running as planned, rather than waiting until the machining cycle has finished.”

The ROCOL ULTRACUT EVO range of operator-friendly water-soluble cutting fluids are inherently resistant to degradation and contain no biocides or skin sensitisers and this makes the fluids pleasant and safe to use. These attributes demonstrate low foaming qualities and reject tramp oil as well to provide excellent cutting performance and residual corrosion protection.

Confirming this, Mr Surman says: “Our operators have had no noticeable effect on their hands where they were getting skin irritation before. Even looking inside the machines, they are much cleaner than they were before and we can only put that down to the old coolant congealing and sticking to the walls and surfaces of the machine.”

The analysis showed that with the ROCOL ULTRACUT EVO 255 solution dilution levels improved from 19:1 to 40:1, reducing A&M EDM’s consumption from 41,000 litres per annum to 20,048 litres per annum. The reduced consumption rate outweighed the increased cost per unit, resulting in a significant cost saving of £16,900 per year.

Alluding to the cost savings that have been derived from implementing the ULTRACUT EVO 255 cutting fluid from ROCOL, Mr Surman adds: “We had an overall look at this, and we used to buy around 10 intermediate bulk containers (IBC) every year and we are now down to 5. We are spending around £17,000 a year less on coolant. However, it’s not just the cost of coolant we are measuring here.”

“There has been a significant drop in the costs and purchasing of our cutting tools, which we can only put down to the cutting fluid and EP additives that are allowing the cutting tools to last longer. We have found that our tool life has significantly improved. I can confidently say that, as we have had a 40% reduction in our tooling spend where roughing operations were being carried out.”

Referring to the waste management of cutting fluid, Mr Surman says: “When the suds kept going-off, we had to dispose of it under our ISO:14001 environmental standard. Now, we are no longer disposing of 10 to 15,000 litres a year due to coolant that has perished.”

Discussing the service, the company has received from MSC and ROCOL, Mr Surman says: “Initially when we were doing the changeover, ROCOL engineers were here every day. They were monitoring and checking vigorously. Now, with the coolant fully implemented, this has been extended to a visit once a month. They come around and do all the checks, all the reports and all the laboratory testing. If we have a problem, ROCOL is only a phone call away and they will pop-in on the same afternoon or the following day. It’s perfect.”

With a vast machine shop, Mr Surman comments on the implementation throughout the facility: “We had our maintenance engineer fit in an IBC and pipe this into every machine, so we have one source with hoses connected to every machine. We now have no spillages on the floor and we are no longer trying to carry tanks around. All in, this is a perfect solution.”

“The ease of changeover from the previous cutting fluid to ROCOL was simple. ROCOL did all of the laboratory work in the background. They came in investigated our work and found a product that was compatible with the materials and jobs we were machining, so we were able to mix. We didn’t need to empty the sumps, we just added it to what was already there, and over some time we are now fully EVO 255 compliant.”

ULTRACUT EVO 255 is formulated to give a long and predictable sump life and provides extra performance in medium and severe cutting operations on a wide variety of ferrous and non-ferrous materials. This has proven ideal for this subcontract manufacturer. In addition to providing the coolant solution, MSC works with ROCOL to deliver specialist and ongoing maintenance and support to A&M EDM, which covers a range of services and periodic analysis to further reduce fluid consumption, extend tool life and reduce downtime. This will help A&M EDM ensure the product continues to perform to its optimum level, no matter what materials are machined.