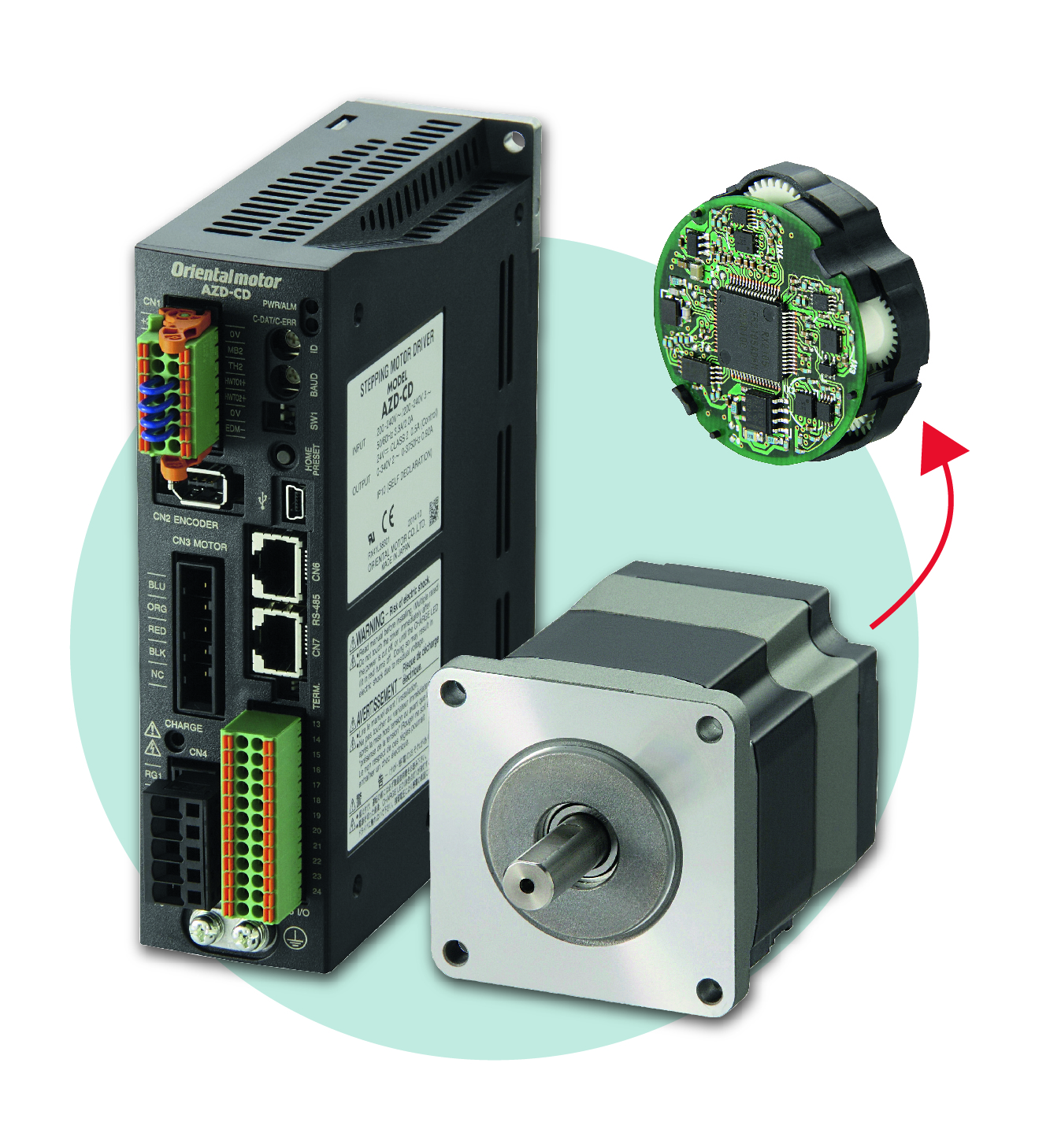

Oriental Motor’s AZ series meets high performance automation needs – with 0.036 degrees/step accuracy – coupled with support for popular communications protocols.

The stepper-based motors have an innovative design which eliminates the need for a PID (Proportional-Integral–Derivative) loop to make constant adjustments, ensuring the correct positioning.

The AZ series’ stepper motor performance means that positional accuracy is increased to 10,000 steps per revolution, or 0.036 degrees per step. In addition, the motor is ready to use “right out of the box” with no tuning required – unlike servo motors which rely on tuning to a variety of parameters to ensure efficient operation.

Communications protocols are vital in today’s automation industry. As factories increasingly adopt connected systems in a ‘smart’ environment, integrators may have a variety of protocols as legacy equipment is combined with new installations.

The AZ series now supports all the communications and control protocols from all major players in the industry: EtherNet IP, EtherCAT, and Profinet, in addition to CANOpen, Modubus RTU, Mechatrolink 2 and Mechatrolink 3. This broad selection of communications options opens up further opportunities in the smart, connected automation industry as well as new and emerging sectors such as automated guided vehicles (AGVs) in warehousing and logistics.

Other advantages of the AZ series are faster acceleration and deceleration compared to an equivalent servo motor. This makes the AZ motor ideal for rapid indexing and applications which require short movements.

In addition, the AZ series is significantly cheaper than an equivalent

power servo motor; it is often as low as half the price, said Paul Jepson, New Business Analyst

Marketing & Distribution, Oriental Motor (UK).

Ideal for applications approximately 750W /1HP and below, the AZ series motors are also recommended for more flexible applications, for example where a belt-driven pulley is used. Unlike a conventional servo motor, the AZ closed loop stepper motors are designed to accommodate even the slightest movements or flexing without affecting performance.