When your products are used across diverse and critical industries, your standards for quality must be uncompromised. Makin Metal Powders – a UK manufacturer of copper and copper alloy powders – use reliable Tinytag data loggers to maintain their commitment to delivering the highest quality metal powders to their customers across the globe.

To guarantee the high quality of their powders, maintain ISO 9001, ISO 140001, and ISO 45001 standards, and comply with European REACH regulations, Makin Metal Powders use Tinytag data loggers to measure temperatures during the production process and monitor ambient temperature and relative humidity in the factory.

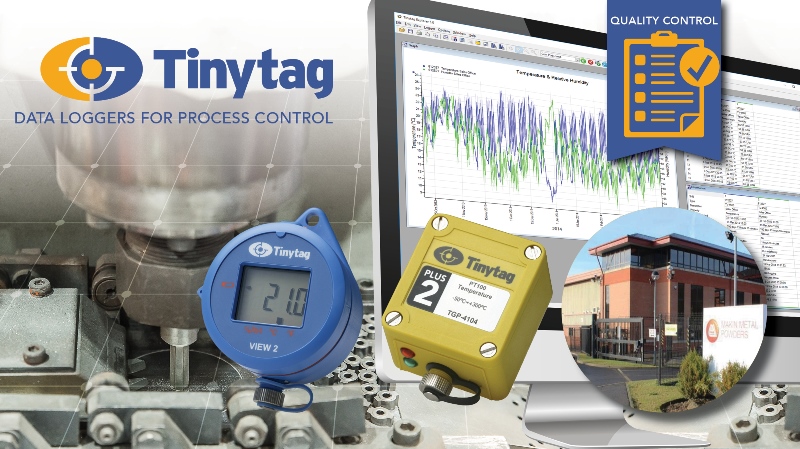

Four Tinytag Plus 2 TGP-4104 high-temperature data loggers are deployed in the laboratory for process monitoring. The data loggers, for use with high-temperature PT 100 probes, can monitor temperatures up to 600°C. With dustproof and waterproof (IP68) casing, the Tinytag Plus 2 range of data loggers is ideal for use in industrial processing.

To measure ambient conditions in the factory, three Tinytag View 2 TV-4506 temperature and relative humidity data loggers are used. The data loggers have digital displays, making them useful for spot-checking temperatures as well as recording data for the long-term, and feature temperature and relative humidity probes with coated RH sensors.

Tinytag data loggers are a reliable choice for process and quality control in harsh manufacturing environments. With a variety of features such as waterproof (IP68) casing and options for extreme-temperature probes, along with easy-to-use data logging software, the Tinytag range offers robust monitoring solutions for manufacturers and quality executives.