Hainbuch has now acquired German automation specialists Vischer & Bolli. With the acquisition of the Lindau based company, Hainbuch is expanding its range of stationary workpiece clamping devices. By incorporating Vischer & Bolli Automation into the Hainbuch brand, the high-precision component clamping experts has expanded their automation whilst offering an even wider range of stationary workpiece clamping devices.

The Hainbuch product portfolio of workholding equipment for turning, milling, EDM and grinding already caters for a remarkably extensive range of workpieces, but now the Hainbuch Group can provide custom solutions for workpieces of up to 100 tonnes or up to 20m in length. Such large-scale projects have already been completed with the incorporation of the new business. The range of stationary devices has been considerably extended with the addition of the Vischer & Bolli Automation brand, and more stationary clamping devices than ever before are now available from stock. Furthermore, Hainbuch can now offer a zero-point clamping system with a modular design to offer a wider range of solutions that use standard components. This extensive modular platform is bolstered by an unprecedented number of specific solutions that can be developed to meet the customers’ needs.

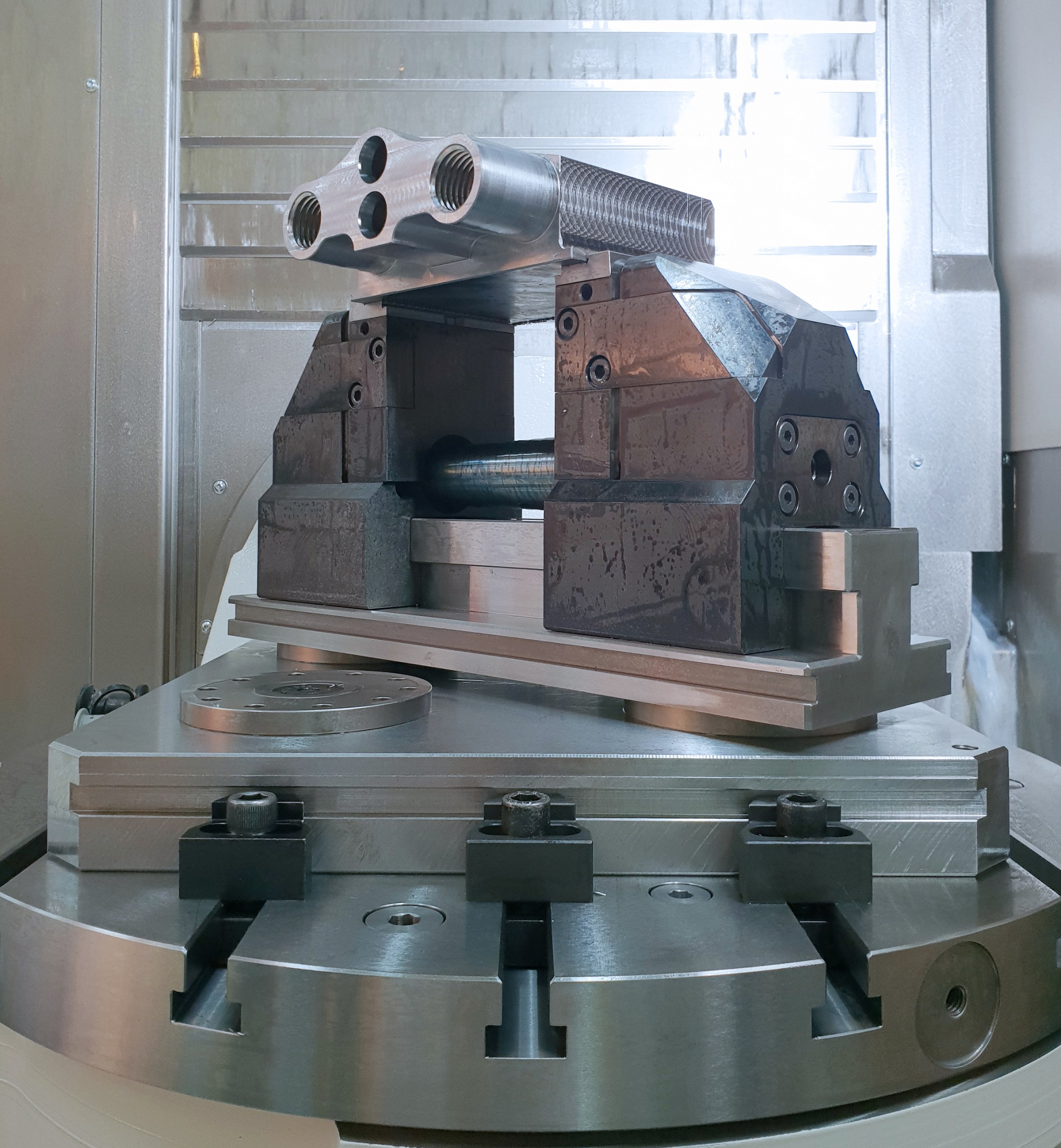

The expanded line of zero-point clamping systems can be screwed onto the machine table to facilitate fast changeovers whilst maximising the clamping area. This is available with pneumatic and hydraulic versions and can be developed with both manual and automated configurations. To clamp the workpiece on the machine base, a vice, clamping tower, modular clamping device, modular clamping system, magnetic clamping plate or a special device can be specified to suit the customer´s requirements. This means that an optimal and economic overall solution can be offered for every workpiece, regardless of shape or size.

The new zero-point clamping system has a universal interface and an accurate clamping mechanism that maximises clamping forces. The low-wear and maintenance system only has three moving parts, extending service life and reducing service and maintenance requirements. Additionally, the handling and push-off functions are integrated into the system and the modular design ensures maximum flexibility to generate significant set-up, time and cost savings.

With standardised locking plates and mounting cylinders for the zero-point clamping system, the patented collet style locking mechanism ensures easy insertion and removal of the workpiece pallets. With a clamping force of up to 30kN, the vibration-free connection between the zero-point clamping system and the workpiece is guaranteed. Direct integration with machine tables, pallets or fixtures can be achieved cost-effectively with installation cassettes. The zero-point clamping system can also be expanded with optional air blow and the integration of support and locking control or external feeds.